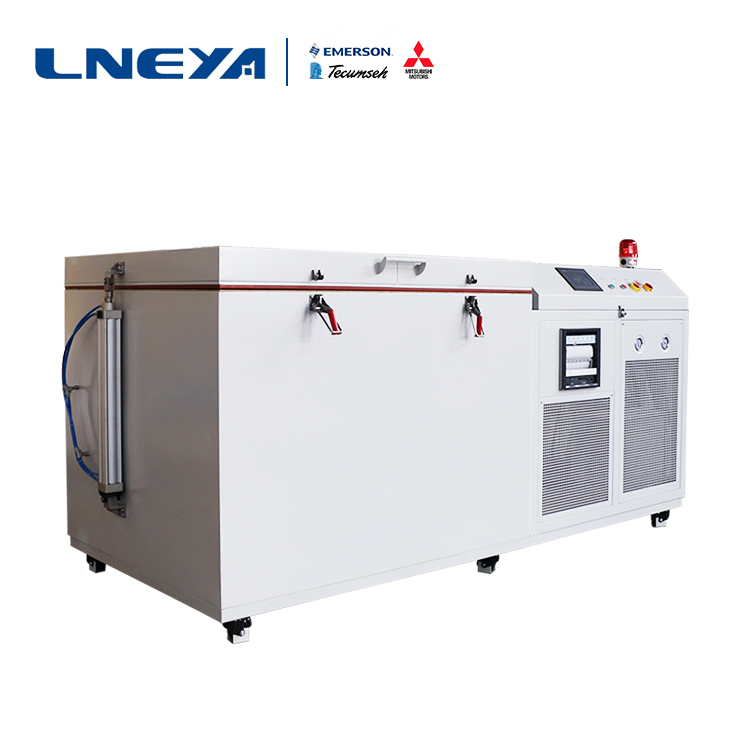

How to solve the fault of the ultra-low temperature refrigerator pressure controller?

If the industrial ultra-low temperature refrigerator encounters a controller-related failure during operation, if it is not resolved in time, the pressure controller may be unavailable.

The pressure controller plays a very important role in the ultra-low temperature refrigerator group. Because of the pressure exerted between each accessory under the high-efficiency working state, the range is different.

In order to reduce the impact of pressure on the ultra-low temperature refrigerator group, the company should regularly check the pressure controller carefully. Only careful inspection can ensure that the equipment operates within a stable and safe pressure range, and the pressure is stable. The problem will be reduced accordingly.

So, where is the pressure controller? The pressure control unit is installed in different positions and there will be different pressures. The range of settings is different, and the effect on the ultra-low temperature refrigerator group is also different. The principle of high pressure and low pressure is different, and the scope of protection for intelligent ultra-low temperature refrigerators is also different. In actual use, there may be excessive pressure, or the pressure is too small. Naturally, there are some internal causes. If you let it develop, it will have a bad influence on the machinery. At this time, the equipment will be It will be a self-protection method by powering off. By reducing this gap, you can try to make the equipment less problematic and the life will increase accordingly. Therefore, it needs to operate within a very safe pressure range. The technology will run steadily.

For ultra-low temperature refrigerator users, the company should ask technicians to train these personnel to let them know the maintenance expertise, what should be checked, and which conditions should be taken care of.

If the relevant configuration of the ultra-low temperature refrigerator is relatively high, the pressure controller failure is relatively small, so it is recommended to choose a reliable manufacturer to purchase.

Related recommendations

-

Refrigeration principle of LNEYA glycol chiller system

978Glycol Chiller System SUNDI -10℃ ~ 200℃, as we can tell from its name, it is to use Glycol as the refrigeration agent for the chiller.In the all air environment, because of the low temperature in the outdoors, it is impossible to use a cooling to...

View details -

Environmental Conditions for Installation of Air Cooled Chillers

1131As we all know, the installation of most machines needs to match the environment and conditions. Of course, our industrial air-cooled chillers are no exception. If the air-cooled chiller is not installed for the first time, it will bring a lot of ...

View details -

Principle Analysis of Glycol Chiller

1132Glycol chiller is an industrial chillerwith glycol as refrigerant. The structure of glycol chiller is roughly the sameas that of ordinary industrial chiller, which is composed of compressor,evaporator, condenser and electric control system. ...

View details -

What are the common connection methods for industrial chillers?

1107There are several connection methods for industrial chillers, which are suitable for pipe connection under different conditions. First, welding connectionWelding is the most important and widely used connection method in pipeline engineering. Weld...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier