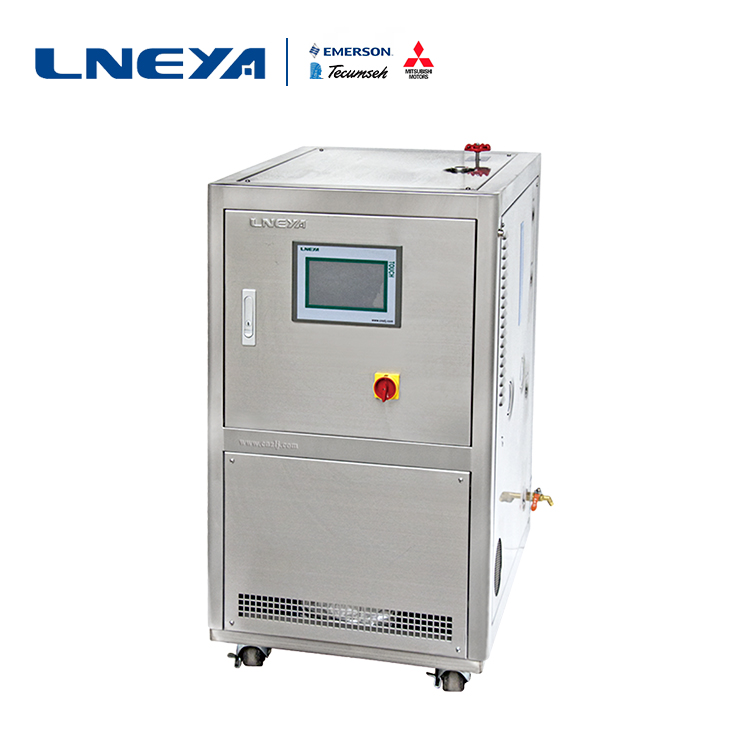

Refrigeration principle of LNEYA glycol chiller system

Glycol Chiller System SUNDI -10℃ ~ 200℃, as we can tell from its name, it is to use Glycol as the refrigeration agent for the chiller.

In the all air environment, because of the low temperature in the outdoors, it is impossible to use a cooling tower to supply the inner area directly with the cold air-conditioner. In addition, the cold air in the outdoors could be used directly as refrigerator source,with glycol as refrigerant, it can introduce the natural cold air into the inner area and supply cold air-conditioner. If we need to heat the outer area and provide cooling for the inner area, we can turn off the chiller and still use the boiler or the urban hot water as the heat source to heat the outer area.

Install plate heat exchanger in the outdoor, and the outdoor cold air is introduced into the plate heat exchanger by the fan. The glycol solution and the outdoor cold air are exchanged in the plate heat exchanger. The cooled glycol solution enters into the air conditioners in the inner area and exchange with mixed air. Then the mixed air enters into the inner room with lower temperature and supply cooling. The temperature of glycol solution rise up, it comes back to the plant heat exchanger in the outdoor again, exchange heat with the cold air in the outdoor and continue this cycling after the temperature is lowered. This way of heat exchange is usually used in the heat recycling system.

It is a very energy-saving way that use glycol as a refrigerant to introduce the cold air in the outdoors to supply cooling for the inner area. All we need to do is to install a plant heat exchanger in the outdoor when it works, the cold water equipment closed, opening the fan and the air conditioners can bring cooling for the inner area. In this way, we can save energy and reduce the cost.

Related recommendations

-

The Analysis Of Ultra Low Freezer’S Price

1170What are the characteristics and functions of ultra low freezer:1. Ultra low freezer can prevent the precision of machine equipment from being influenced by the change of oil temperature in the process of operation. 2. Ultra low freezer can preven...

View details -

Rapid temperature change test chamber temperature control instructions

1071The selection of the humidity range of the rapid temperature change test chamber should be noted that the corresponding temperature range should be indicated after the humidity index or the dew point temperature should be given. Because relative h...

View details -

High-power industrial refrigerator evaporator maintenance precautions

1032High-power industrial refrigerators are used in industrial cold processing. Evaporators in high-power industrial refrigerators are one of the most important components and one of the factors affecting the cooling effect of high-power industrial re...

View details -

How to Deal with the Poor Dissipation of Low Temp Chillers

1187Low temp chiller products contribute a lot to various industrial production, and at the same time, help to improve the labor efficiency of industrial production. With the development of China's economy and the improvement of production process req...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier