Global service

Served more than 30,000 customers.

Exported to more than 20 countries.

Certification patents

Has obtained CE certification, SGS certification, ISO certification.

After-sales service

Provide comprehensive technical training.

With 24/7 solutions.

Professional team

Founded in 2010, with 15 years of industry experience.

20% of employees are technicians.

Quality control

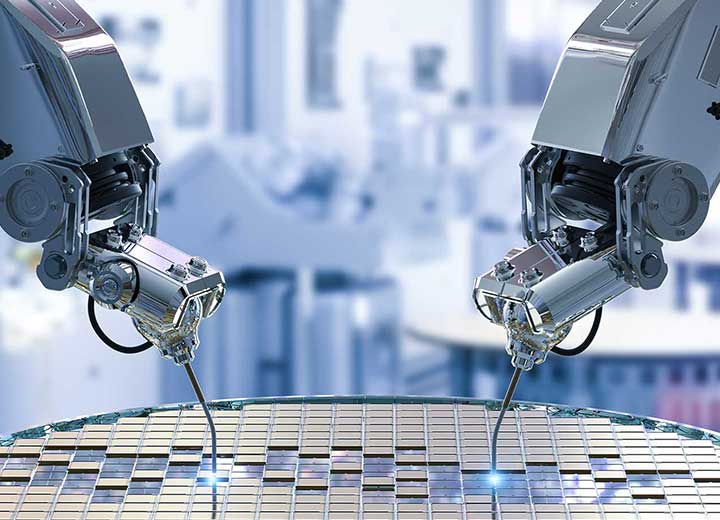

Visual inspection.

Performance test.

Electrical safety test.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier