Product Centre

KRY Series Cooling Heating Control Temp & Flow System

Introductions

The object under test is connected to a test platform adapter, and the component is cooled and heated by ethylene glycol water solution inside the component. The tested component needs to undergo a specific temperature change curve, and the temperature change is recorded. The temperature change usually ranges from -40℃ to 100℃. (Extended to 150°C) When conducting tolerance tests, they are usually performed in cycles.

KRY Multi-channel Series Battery Testing Thermal Control Solutions

Introductions

Control temperature & flow system supports one to many, meaning that one refrigeration and heating temperature control flow host can control 2-6 different test benches or demand temperature control flow devices. Support two one to many modes, one is that temperature/flow/pressure can be independently controlled (T-series), and the other is that temperature is consistent across multiple groups, and flow/pressure is independently controlled (S-series).(LNEYA’s chiller supports both indoor and outdoor options.)

Left & Right Multi-layer Test Chamber

Introductions

Left and right multi-layer test chambers provide temperature range -80℃~+150℃ wide temperature range temperature control, no-load temperature uniformity ±1℃, temperature accuracy ±0.1℃, to meet the needs of diverse scenarios.

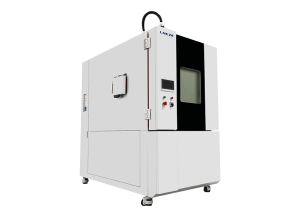

GD Series Rapid Temperature Change Test Chamber

Introductions

It is suitable for environmental stress screening tests. By performing environmental stress screening on products, it accelerates the discovery of product design defects and improves product reliability. Many industrial fields have realized that high-speed temperature change cycle tests can find unreliable systems that have entered the production test stage. It has been used as a standard method to improve quality and effectively extend the normal working life of products.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier