Manufacturers of temperature simulation systems for chip testing analyze why chip testing is necessa

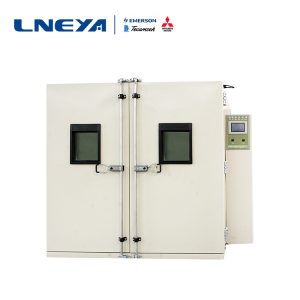

When users run the chip test temperature simulation system, they need to understand the chip test clearly. For this reason, the manufacturer LNEYA analyzes the relevant knowledge of the chip test and provides you with more detailed knowledge.

Function failure means that a certain function is not implemented, which is often caused by design. Usually it is simulated to verify the function before the design stage to ensure, so usually design a chip, simulation verification will take about 80% of the time . The performance is unqualified, and a certain performance index is not required. For example, a 2G CPU can only run to 1.5G, and the digital-to-analog converter has 12 effective bits, but only 10 bits under the required conversion speed and bandwidth. , And lna’s noise figure index does not meet the standard and so on. This kind of problem is usually caused by two problems, one is that there is not enough margin when designing the system in the early stage, and the other is that the physical implementation layout is too bad. Such problems are usually verified by post-simulation. Disqualification caused by production. The reason for this problem is to mention the production of single crystal silicon. Those who have studied semiconductor physics know that single-crystal silicon is a regular face-centered cubic structure, and it has several crystal directions. Usually, we grow the single crystal according to the 111 crystal direction. However, due to various external factors, such as temperature, pulling speed, and various randomness of quantum mechanics, misalignment occurs during the growth process, which is called a defect.

Another reason for chip defects is caused by ion implantation, and even irregular annealing can not correct the irregular structure. These problems in semiconductors will lead to the failure of the device, which will affect the entire chip. Therefore, in order to find out the failed or semi-failed chips after production, special test circuits will be added at the time of design, such as testing in analog, testing logic in digital, and testing storage, to ensure that all are delivered to customers. It’s an ok chip. And those failed or semi-failed products are either abandoned or castrated and sold as low-end products.

When running the chip test system, if the chip in the chip test system is found to be unqualified, it needs to be removed in time to continuously improve the chip’s operating efficiency.

(If there is any infringement from the source network of this article, please contact Wuxi Guanya to delete it. Thank you.)

Related recommendations

-

Description of pump selection in steam-saturated system temperature control unit

1043The steaming system temperature control unit is one of the more used equipment in the pharmaceutical chemical industry. The performance of the LNEYA steaming system temperature control unit depends on the design of the whole system and the specifi...

View details -

Methods for Chiller Manufacturers to Ensure Product Quality

973Before producing the industrial chiller, the chiller manufacturer will consider the applicable industry, refrigeration capacity, structure, etc., and consider the actual use environment during design and assembly to optimize some functions. In ord...

View details -

What causes sediment in the use of the chiller cooler?

866A chiller is a water-cooled unit that uses water circulation to provide a constant temperature, constant flow and constant pressure cooling water. The LNEYA cold water system has its own working principle, that is, a certain amount of water is inj...

View details -

Step-by-step test box brand advantage description

1229The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier