What should do if the equipment of the thermal shock test chamber does not reach the set temperature

The choice of the manufacturer of the thermal shock test chamber is related to the quality of the thermal shock test chamber. Once the quality is set, the temperature setting of the equipment will not be closed. What should I do if I encounter the temperature setting problem?

The temperature set by the thermal shock test chamber is not up to the possibility that the heat exchange humidification tube is broken. You can either repair the factory or replace the new thermal shock test chamber directly. In the high temperature test, if the temperature does not change. When testing the temperature value, the electrical system can be inspected to eliminate the fault one by one, or the temperature probe may be broken, causing the device to not work when the water temperature is lower than the set standard temperature or 37 degrees.

The temperature and temperature of the thermal shock test chamber is too long or the heating tube is aging and damaged. When the actual water temperature is far below 37 degrees, the equipment has not worked, or the work is not working. If the temperature rises directly to cause over-temperature protection, the controller fails and the control instrument must be replaced. If the temperature is too high, you need to set the PID setting parameters first.

If the temperature rises very slowly, it is necessary to check the air circulation system to see if the regulating baffle of the air circulation is normally turned on. If the temperature of the thermal shock test box rises very quickly, check whether the motor of the air circulation is running normally. Because there is a time limit for use, so the running time is too long, it is inevitable that there will be some kinds of various faults, usually pay attention to regular maintenance and maintenance, generally can be largely avoided. If you encounter a large technical problem, you should seek solutions in time with the manufacturer.

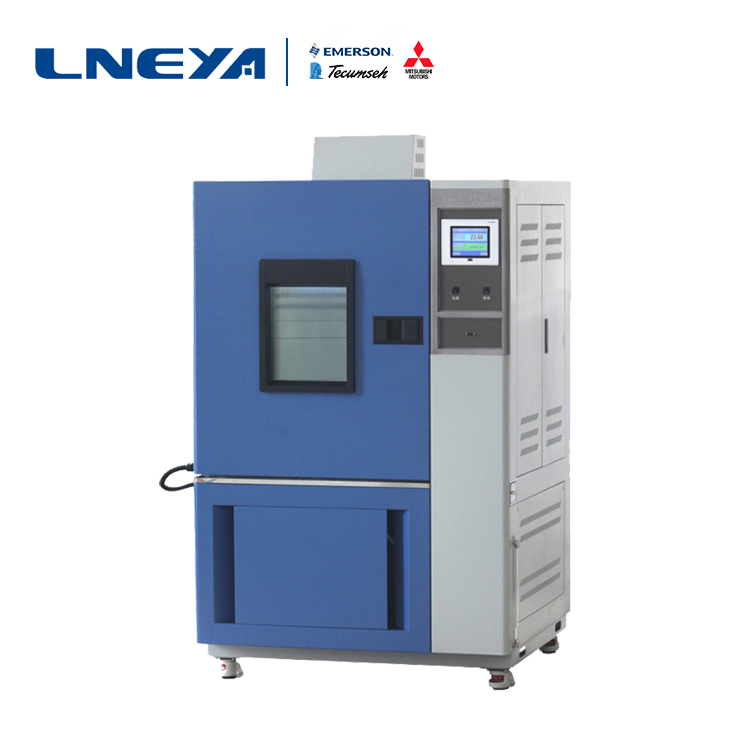

LNEYA thermal shock test box manufacturer is a professional hot and cold impact test box manufacturer integrating R&D, production and sales. It has more than ten years of experience in refrigeration and heating equipment production, and has reached cooperation with many domestic enterprises.

Related recommendations

-

Accessories and accessories for heating and cooling systems

1681The selection of heating and cooling system is quite important, not only price and temperature control, but also quality should be taken into consideration. Besides, you should also pay attention to the accessories of heating and cooling system. F...

View details -

Matters Needing Attention in Replacing Refrigerant Oil of the Screw Chiller Factory

1553The refrigerant oil in the screw chiller factory needs regular inspection and replacement. We all know that different grades of refrigerant oil cannot be mixed together, otherwise it will cause abnormal or strike conditions of the screw chiller fa...

View details -

How to Solve the Problem of Compressor Noise in Industrial Low Temperature Chiller?

1821In industrial low temperature chiller, compressor operation will produce noise, but only thedifference of sound size. Generally speaking, there will be some problems if the noise is too large. So, how to solve the problem of compressor noise?Gener...

View details -

How to save energy in the vacuum chamber refrigeration heating thermostat control unit

1864In the environment of energy-saving and emission-reduction operation, how to operate the LNEYA vacuum chamber cooling and heating thermostat control unit is very important. Let's take a look at a few tips to reduce the consumption and see how to u...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier