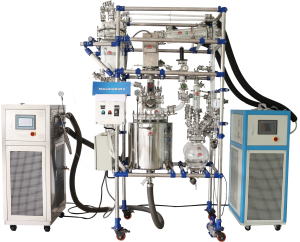

Closed laboratory circulator enamel stirring tank refrigeration and heating system

In the chemical industry, reaction kettles and various stirring tank containers are often seen for various chemical reactions. So, how much do you know about laboratory temperature controlled circulators?

1、 The principle of laboratory temperature control circulator

The laboratory temperature control circulator is a kind of equipment that integrates heating and cooling functions. It can control the medium temperature and material temperature, especially for external applications that need rapid heating and cooling. It can control the temperature rise and fall and constant temperature of the enamel mixing tank, and it is suitable for the control of heat demand and Exothermic process in the reaction process.

The laboratory temperature control circulator circulates the hot medium into the jacket of the enamel mixing tank to achieve heating or cooling operations. Equipped with an accurate temperature control system that can set the temperature according to demand and adjust it in real-time to ensure that the temperature of the enamel mixing tank is always in the desired state.

2、 Application effect of laboratory temperature control circulator in enamel stirring tank

A、The rapid heating and cooling ability of the laboratory temperature control circulator can greatly shorten the production cycle and improve production efficiency. For the curing stage of the enamel mixing tank, the temperature can be quickly raised to the set value, thereby accelerating the curing speed and reducing production time.

B、The laboratory temperature control circulator can accurately control the temperature of the enamel mixing tank, ensuring temperature consistency during the manufacturing process, and avoiding product quality issues caused by temperature fluctuations.

C、The laboratory temperature control circulator has a stable protection device that can monitor and protect the temperature and pressure of the enamel mixing tank. In case of abnormal situations such as overheating or overpressure, the laboratory closed circulator will automatically stop running and issue an alarm to ensure the stability of the operators.

The laboratory temperature control circulator achieves independent heating and cooling in the processing field of enamel mixing tanks, which can improve production efficiency, ensure product quality, and bring more convenience and benefits to the development of the industry.

Provide 7 * 24 free consultation and comprehensive solutions

Email: sales@cnzlj.com

WhatsApp: 086 13912479193

Related recommendations

-

The Analysis Of How To Maintain The Low Temperature Circulator In Daily Life

1141Guanya is a leading role in heating cooling circulator. It provides the customers with proposal and technology of controlling the cold and heat, temperature control system with stable property, extending the service life of heating cooling circula...

View details -

Performance description of recirculating chiller for bioreactor

1055The recirculating chiller is suitable forthe high and low temperature reaction of various stainless steel, enamel,titanium alloy reactors, emulsifiers, injection molding machines, mixingvessels and various bioreactors. Other bioreactors in diff...

View details -

What are the components that improve the performance of industrial chillers?

1110Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core compo...

View details -

How to choose an industrial water chiller system

1146Want to buy an industrial water chillersystem? Want to buy a reliable industrial water chiller system? Want to buy ahigh-quality industrial water chiller system? How to buy?1. Process requirementsRegardless of equipment, LNEYA providesusers wit...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier

Submit for consultation

We will reply to you within 24 hours