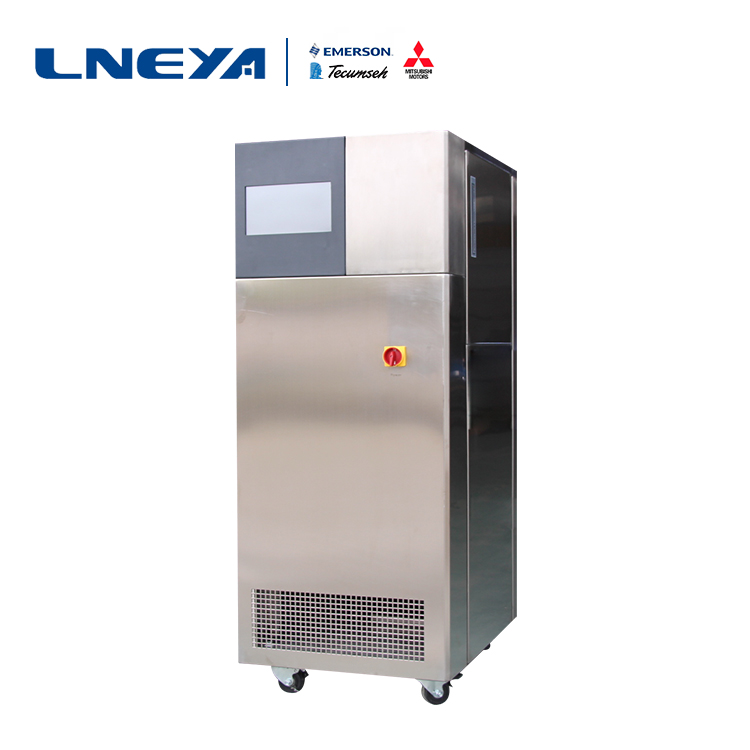

Protection device details of circulating fluid temperature control device

The circulating pump overload protection function is to cut off the main power of the circulating pump when the circulating liquid temperature adjustment device is too large. Press the green button when resetting; the red button is the stop button, which is used during the test. When frequent protection, please check whether the voltage is under voltage (undervoltage is less than 15%, the power protector is not working), undervoltage is increased into current, forming protection. At this time, a Phillips screwdriver can be used to adjust according to the “△” direction. Current.

Different circulating fluid temperature adjustment devices are equipped with different high and low voltage protectors. The high and low pressure protectors will protect the compressor with reference to the suction and exhaust pressure of the compressor to ensure the normal operation and operating life of the compressor. The high and low voltage protectors are divided into mechanical and electronic high and low voltage protectors. When the high and low voltage protectors are protected, manual reset is required. Press the red highlight button to reset. When the high and low voltage protectors generate protection, manual reset is required. Push the red arrow to reset. The electronic high and low voltage protector is automatically reset.

The circulating fluid temperature adjustment system provides a lot of accessories for equipment protection to ensure the safety and stability of the equipment. The over temperature protection has an independent high temperature temperature limit switch, which can set a relatively large temperature value through this temperature switch (please note) Meet the relatively large operating temperature range of the equipment and the temperature range of the heat transfer oil).

Inspiratory temperature protection with independent compressor suction temperature protector to protect the compressor from excessive suction temperature, ensure that it is within 65 °C (non-recycling liquid temperature adjustment device manufacturer authorization, do not modify, will directly affect the compressor Cooling capacity).

Circulating fluid temperature adjustment device The oil pressure difference protector is generally applied in large equipment. Depending on the equipment, the oil pressure difference protector is different. Press the upper ink green button when resetting. Other types of oil pressure difference protectors are similar. The reset button can be reset by itself. Other protections of the circulating fluid temperature adjustment device include phase protection, phase loss protection, overvoltage and undervoltage protection, leakage protection, and water shutoff protection.

The protection devices of different circulating liquid temperature adjustment devices are different. No matter what brand, the safety devices are more important. We need to pay attention to them. We must carefully check before purchasing to ensure the operation of the equipment.

Related recommendations

-

How to install and use the reactor temperature control system?

1671Many users are going to start the installation after purchasing the reactor temperature control system. What should be paid attention to during installation? When installing the reaction kettle of the reactor temperature control system, it is nece...

View details -

Description of the principle and mode of industrial water chiller refrigeration cycle

2072Anyone who knows about industrial waterchillers should know that it uses compressors to achieve the cooling effect.So, how does it work when refrigerating?1. Vapor compression refrigeration cycle.After cooling and pressurizing the vaporfrom the...

View details -

How to solve the problem of insufficient cooling capacity of semiconductor cooling cycle system?

1919The semiconductor cooling cycle system is a device for cooling the semiconductor heating part. LushiA reminds that if the cooling capacity is insufficient during the operation, it is necessary to check in time to see if something has gone wrong. W...

View details -

Good news! Wuxi Guanya LNEYA Refrigeration gets a new name

3980According to the `` Notice on Publishing the Evaluation Results of Unicorn and Gazelle Enterprises in the 2019 South Jiangsu National Independent Innovation Demonstration Zone '' issued by Jiangsu Sunan National Independent Innovation Demonstratio...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier