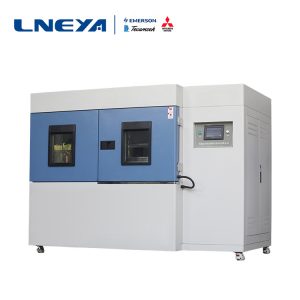

Cold and hot shock constant temperature and humidity test chamber operation steps

When selecting the appropriate model of the LNEYA hot and cold shock constant temperature and humidity test chamber, you need to pay attention to the operation and installation steps. The user needs to be well prepared for the installation work.

The hot and cold shock constant temperature and humidity test chamber should be noted before use. The power supply voltage should be turned on. After the fan is started, open the door and select the required impact height. Then close the door and press the up and down position. Then stop rising.

Then, open the door and insert the safety pin to protect it in the future operation. Place the tested object in the center of the thermal shock constant temperature and humidity test chamber, and then place the crossbar on the sample. Hold the battery at the center, dial the safety latch, and close the door. Press the impact button and the falling ball weight is free to drop and complete a test.

The hot and cold shock constant temperature and humidity test chamber should be noted in use. The test sample should be a non-deformed sample or a well-packaged sample to avoid affecting the test conclusion. Before placing the sample for each operation, be sure to insert the full plug. Well, it is strictly forbidden to operate without a safety plug to avoid unnecessary safety accidents.

The installation proposal of the thermal shock constant temperature and humidity test chamber shall be installed by a special operator, and the installation of the external operator shall be avoided as much as possible to avoid damage to the equipment.

Related recommendations

-

The Structural Characteristics Of Heating Cooling Systems SST-15 SST-20

1517Anyway, Heating Cooling Systems SST-15 SST-20 is a high-performance product with comprehensive functions and simple operation. It will help customers expedite the experiment and save resources so that improve work efficiency.,

View details -

The Application of Cold Plate Freezer

1424The refrigeration system of cold plate freezer adopts secondary super-cooler technology with the rapid refrigeration and low limiting temperature. It uses imported brand name semi-hermetic piston compressors, semi-hermetic piston compound compress...

View details -

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1750The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

View details -

High and low temperature hot and cold water cooling machine for battery motor test

1590LNEYA high and low temperature cold and heat integrated water cooler is used in battery thermal management of new energy electric vehicles. The following is the relevant principle applied in thermal management.The high and low temperature cold and...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier