Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

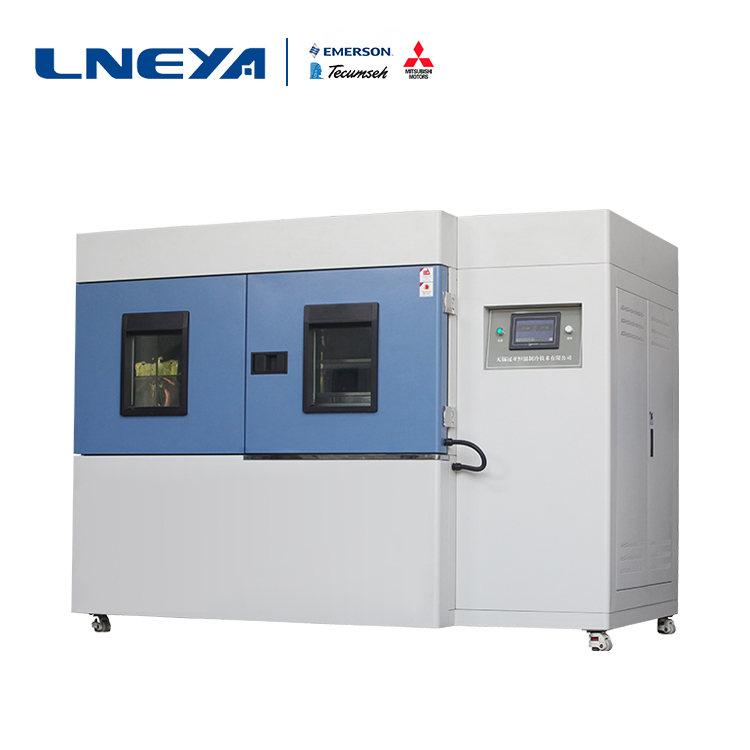

The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better?

The high and low temperature impact test chamber filter is fouled and the exhaust volume is reduced. Need to clean the filter in time to solve the problem. The suction pipe is too long, and the pipe diameter is too small, so that the increase of the suction resistance affects the gas volume; it is necessary to increase the pipe diameter of the suction pipe in time and shorten the length of the suction pipe.

Because the air compressor is designed according to a certain altitude, intake temperature and humidity, how to use it at high altitude, the suction pressure will decrease, and the exhaust volume will be insufficient. It is necessary to replace the appropriate high and low temperature impact test chamber compressor in time.

The cylinders, pistons and piston rings are severely worn and out of tolerance, which increases the relevant clearance and increases the leakage, which affects the displacement. If it is necessary to be in time for normal wear and tear, it is necessary to replace consumable parts in time, such as piston rings. If the installation is inaccurate and the gap is left in a timely manner, it should be corrected according to the drawings.

The packing box of the high and low temperature impact test chamber is not strict, and the negative air volume is reduced. The reason is firstly because of the divergence requirements in the manufacture of the stuffing box itself; secondly, because during the installation, the center of the piston rod and the stuffing box is not well, causing air leakage due to wear and strain; generally, the lubricating oil is filled in the stuffing box. It can function as lubrication, sealing and cooling.

Metal fragments or other debris are dropped between the valve seat and the valve plate, resulting in a tight seal and a leak. This not only affects the amount of exhaust, but also affects the pressure and temperature changes between the two stages. This problem may arise because of the manufacturing quality problems, such as valve warpage, and the second, because the valve seat and the valve plate wear. Severe and leaking.

The valve spring force does not match the gas force. If the elastic force is too strong, the valve plate will be opened slowly. If the elastic force is too weak, the valve plate will not be closed. This will not only affect the air volume, but also affect the increase of power and the life of the valve disc and spring. At the same time, it also affects changes in gas pressure and temperature.

The pressing force of the compression valve is improper. If the pressing force is small, it will leak air. Of course, it will not be too tight, which will deform and damage the valve cover. The valve has a fault, the bonnet has a fever, and the pressure is not normal.

These faults of the high and low temperature impact test chamber need to be solved in time after some faults are found. At the same time, it is necessary to pay more attention to maintenance and reduce the failure rate.

Related recommendations

-

Vocs equipment industry heat exchanger type description

1573Every accessory in the vocs device has its function, so every accessory in the vocs device can't be less. So what is the heat exchanger in the Wuxi LNEYA vocs device? What are the main types? Tank heat exchanger: Compared with the traditional heat...

View details -

Operating Instructions For the Low Temperature Test Chamber

1672The low temperature test chamber is a necessary test equipment in aviation, automobile, household appliances, scientific research and other fields. It is used to test and determine the parameters and performance of electrical, electronic and other...

View details -

Refrigeration Explanation for Screw Compressor of Low Temperature Chiller Circulator

1714Because of the different compressors, the performance of the low temperature chiller circulators is also different. Screw compressors are different from piston compressors, and the structure is more precise. Therefore, if users need to choose the ...

View details -

Characteristics of Industrial Constant Temperature Recirculating Chiller

2132Points for attention in the use ofindustrial constant temperature recirculating chillerIndustrial constant temperature recirculatingchillers are widely used in pharmaceutical, chemical and laboratory. Next,let's introduce the characteristics...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier