Automotive Coolant (ELC) Test Benefits and Introduction to coolant conditioner system

The cooling system is one of the main components of the engine. Its main function is to protect the engine from corrosion, pitting, corrosion and overheating. It is compatible with different engine materials and lubricates the engine cooling pump. If the engine coolant quality is reduced and deteriorated prematurely, the engine and the coolant system may be severely damaged.

Automotive cooling systems are critical to the efficient performance and long life of the engine, and about 50% of downtime can be attributed to problems related to the cooling system. If undetected, problems in the cooling system may spread to the gearbox and hydraulic system cooled by the heat exchanger, which may cause serious engine failure. Quality testing helps ensure that the coolant meets the harsh physical environments of today’s engines. Monitoring the physical and chemical properties of the coolant is essential to check its condition.

Antifreeze, also known as coolant, keeps the engine in optimal condition. At -20 degrees, your car is outside all day, but it can start immediately. Or it may be 105 degrees, and your car is whistling on the highway without danger of overheating. For example, when 50/50 water is mixed with water in a car radiator, the water no longer freezes at 32 degrees Fahrenheit. Instead, the water will freeze at temperatures below -37 degrees. Similarly, although only water usually boils at 100 degrees, the antifreeze is mixed with the same amount of water until it reaches 106 degrees before it can boil.

The most effective and economical way to monitor cooling systems is by sampling the coolant. Assess the chemistry of the coolant and monitor the condition of the cooling system. The goal of coolant analysis is to monitor the health of the coolant and the health of the entire cooling system. General test laboratories use advanced liquid chromatography to obtain fast but accurate results. Coolant testing options include antifreeze, corrosion inhibitor, cooling system, coolant, glycol, performance, boiling point, freezing point, trace chemical analysis, and other tests as needed, such as hot surface testing, dynamic heat transfer testing, and Coolant aging test …

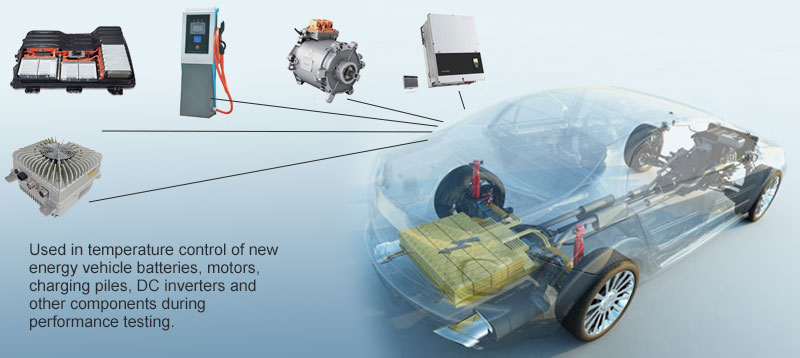

Lneya’s KRY series of cooling and heating machines developed and produced in 2019 is designed to monitor and control the temperature of coolants, motors and batteries in the automotive industry (traditional and new energy) during testing. Simple principle: the object to be tested is attached to the test platform. After the test program is started, the cooling and heating machine KRY equipment takes the heat inside the part through the cooling and cooling of the ethylene glycol aqueous solution, and provides the temperature required for the test by heating. . The temperature change is usually in the range of -40 to 100 degrees (expandable to 150 degrees). When performing tolerance tests, the conditioning unit usually requires infinite cycles.

Lneya’s coolant conditioner system is equipped with a powerful circulation pump, and at the same time ensures the transmission of high-viscosity liquids during the test. The frequency output is controlled by frequency conversion or proportional control valves to achieve high-precision control of 5% to 100% of the total range. During the test, it can keep the water / coolant temperature constant, eliminate the temperature error in the engine test, and the specific temperature curve and recorded temperature changes are conducive to studying the performance of the same engine at different water temperatures. For the charge management test of the power battery, The precision temperature control device used for testing permanent magnet synchronous motors, switched reluctance motors, asynchronous motors and their controllers can realize local + remote control mode through the LCD control panel.

As we all know, a temperature control device combined with a test bench, whether it is a test company or a laboratory, requires a lot of cost. Lneya has upgraded the R & D and production of the coolant conditioner system, which can realize that one device can achieve multi-channel output, and each channel can control different flows without interfering with each other. It is especially suitable for the control of lifting temperature and constant temperature, cooling and exothermic process control in the testing of new energy batteries and motors.

Related recommendations

-

How to choose a glass reactor? How to match the temperature control system?

942Glass kettle reactors are required for many laboratory equipment and are generally used with temperature control systems. In the chemical and pharmaceutical fields, the imported glass reactor is basically a necessity, and the refrigeration heatin...

View details -

Why can ethylene glycol chillers be used for polymerization and coupling reactions

8741. Polymerization heatingGenerally, the raw materials ofpolymerization reaction are some flammable solvents, and heating up quickly maycause local temperature to be too high and cause accidents. Everypolymerization reaction has its proper react...

View details -

How to remove ultra-low temperature refrigerator shell and tube condenser scale?

1099Low-temperature refrigerator ultra-low temperature condenser scale removal In general, we have three methods, namely mechanical descaling, chemical pickling and descaling, and electronic magnetic water separator descaling. Low-temperature refriger...

View details -

Introduction to the structure and application of industrial refrigerators

960Industrial refrigerators are usually called industrial refrigerator boxs, and low-temperature freezers.Temperature range: -150℃~-20℃. Industrial refrigerators can be divided into vertical and horizontal types. Most of them use imported compressors...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier