Advantages of low temperature cooling recirculating chiller

Low temperature cooling recirculating chiller is a kind of refrigeration using compressor, and the circulating pump provides cold source to maintain the temperature range from – 2 5℃ to 30 ℃. The refrigeration recirculating chiller has a space-saving vertical configuration and good heat dissipation effect. It can effectively control the external closed liquid loop when the temperature is far lower than 0 ℃. It is suitable for water, oil or other media of the manufacturer. All recirculating chillers can be connected with other equipment through hoses and used as a constant temperature source.

The high and low pressure of the low-temperature recirculating chillers are 2.5bar and 0.7bar respectively. The air-cooled fully enclosed compressor unit is used for refrigeration, microcomputer intelligent control, automatic opening and delayed closing of the refrigeration system, overheating and current multiple protection devices. It is widely used in petroleum, chemical industry, medicine, life science, metrology, light industry, scientific research and other fields.

Advantages of low temperature cooling recirculating chiller:

1. One of the characteristics of the refrigeration cycle is the large single pressure ratio, but with the increase of the pressure ratio, the efficiency of the screw chiller decreases and the power consumption is large.

2. In order to expand the application range of screw chiller, improve the performance at low temperature and achieve the purpose of energy saving.

3. Taking advantage of the unidirectional operation of suction, compression and exhaust of the screw machine, an intermediate air supplement orifice can be set at a certain position where the rotor starts to compress, so that the single screw refrigerator can operate according to two compression, that is, the screw chiller with economizer.

4. It is usually used when the evaporation temperature is – 25 ℃ ~ 30 ℃. Compared with the original single screw chiller, the refrigeration capacity and refrigeration efficiency are greatly improved, and electric energy can be saved at the same time.

Related recommendations

-

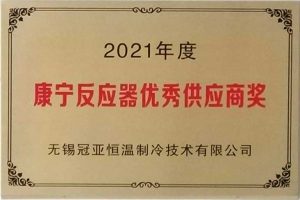

Won the “Excellent Supplier of Reactor Temperature Control Equipment in 2021”

4526LNEYA was awarded the "2021 Excellent Supplier of Reactor Technology" by Corning, a Fortune 500 company in the United States. Since 2015, LNEYA has won this award for 7 consecutive years. Therefore, in the reactor manufacturing industry, we have ...

View details -

What are the effects of power failure on liquid nitrogen cryogenic cold box?

1804Different industries have different temperature requirements for liquid nitrogen cryogenic cryostats. Of course, there are many types of cryogenic cryostats. The refrigeration methods used in different industries are different. Wuxi Guanya LNEYA u...

View details -

Advantages of Industrial Chillers in Refrigeration

1665In recent years, the manufacturing industryhas entered a golden age. The market competition is fierce, and therequirements for product quality have been greatly improved. In fact, in theprocess of improving product quality, manufacturers oft...

View details -

How to choose low temperature and high temperature simulation equipment for material aging test?

1723Material aging testing is used in many industries, but how to choose high-quality low-temperature and high-temperature simulation equipment is very critical, because temperature plays an indispensable and important role in the testing process. LNE...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier