How to control the emulsification temperature of the emulsifier?

A good cream product is not only reflected in the quality of raw materials, but also has a great influence on the emulsification process during production, such as the texture and stability of the product, and the temperature control during production will affect the cream product.

Generally speaking, the emulsification temperature is determined by factors such as the melting point of the high melting point substance contained in the two phases, the type of emulsifier, the solubility of the oil phase and the water phase, etc. In addition, the temperature of the two phases needs to be kept at nearly the same state, especially for waxy and fatty oil phase components with a higher melting point, that is, the temperature is above 70. They cannot add a low-temperature water phase during emulsification to prevent emulsification before emulsification. Crystallization of wax and fat results in blocky or rough and uneven emulsion. The emulsification temperature sometimes also affects the size of the emulsion particles. For example, when the fatty acid soap anionic emulsifier is generally used for emulsification by the nascent soap method, the emulsion particle size is about 1.8-2.0 microns when the emulsification temperature is controlled at 80 degrees. When emulsifying, the particle size is about 6 microns. However, when non-ionic emulsifiers are used for emulsification, the effect of emulsification temperature on particle size will be relatively weak.

When emulsifying, the temperature of the oil and water phases can be controlled at 75 to 85 degrees. If the oil phase has components such as wax with a high melting point, the emulsification temperature should be higher at this time. In addition, if the viscosity increases during the emulsification process, it will also affect the stirring, so it is necessary to increase the emulsification temperature appropriately.

Tank bottom emulsifier, pipeline emulsifier, vacuum emulsifier, dispersion emulsifier, etc. are used in daily chemical, fine chemical, biopharmaceutical and cosmetic production. In the mixing and stirring process, a large part of material processing requires heating function to achieve the effect of high-quality finished products.

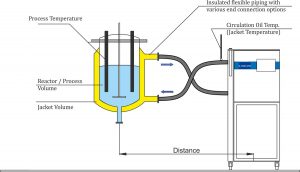

Heating methods include electric heating and dynamic heating. Electric heating requires a built-in functional module of the emulsifier, which can adjust the temperature easily and portablely, but the temperature uniformity is poor and cannot be cooled. Dynamic heating is our dynamic temperature control system SUNDI series. Heat transfer oil with different temperature points is used as the medium, which can not only heat but also cool. The emulsifier itself and the temperature of the material can be set to control the temperature. range, SUNDI-135 is used by customers for cooling and heating of emulsifiers. The temperature of the material in the reactor can be controlled and the temperature rise and fall curves can be displayed on the control panel, the temperature difference can be set independently, and the temperature control accuracy can also be adjusted.

Related recommendations

-

The cooling circulation system is used to collect the non-condensable tail gas in the distillation s

1549Most rectification towers are two-stage condensation. The first stage uses cooling water, mainly condensing the top steam, and the second stage uses chilled water or ethylene glycol, which is mainly used to treat tail gas and remove a small amount...

View details -

What are the factors that affect the price of industrial heating equipment in the industry?

1443The price of heating and temperature control equipment is a part that many customers care about. The price is related to the brand, raw materials, and technology. At the same time, the technical parameter configuration of the product also has a gr...

View details -

Introduction to heating cooling temperature control system of fermentation tank

1763In the pharmaceutical and biochemical industry, the fermentation tank needs to be equipped with a heating, cooling and temperature control system to control the temperature in the system. The LNEYA refrigeration, heating, cooling and temperature...

View details -

Low temperature cooling chiller for chemical material manufacturing process

15051. Temperature sensitive reactions control many chemical reactions that are highly sensitive to temperature, especially in the synthesis of polymer materials, pharmaceutical intermediates, and other fine chemicals. Low temp...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier