About the size and installation height of refrigeration heating temperature control system equipment

Whether it is biopharmaceutical, traditional Chinese medicine or chemical pharmacy, pharmaceutical companies are all related to chemistry, because the extraction and synthesis of pharmaceutical ingredients are all in the form of chemical products. Therefore, as long as there are many links in the process, there are explosive substances such as acetone, alcohol, etc. There are also raw materials in the warehouse, dust in the workshop, and pressure in the reactor.

Temperature control equipment is essential for these enterprises, and the price is relatively expensive, so such customers are customized explosion-proof cooling and heating units. The explosion-proof standard of our LNEYA is in accordance with national regulations, the explosion-proof mark is Expxdmb Ⅱ CT4, and the explosion-proof qualification is just GYB091118. The positive pressure explosion-proof cabinet is composed of a positive pressure chamber and a control chamber. The positive pressure chamber is used to install various non-explosion-proof instruments or electrical appliances. The control chamber is composed of an explosion-proof control box and a pressure control system. The isolation explosion-proof mark is EXd ⅡBT4, and the electrical cabinet adopts explosion-proof type. Therefore, during the initial communication, our technicians will confirm with the user whether there are explosion-proof requirements.

Here we mainly introduce the hardware data of our LNEYA refrigeration heating temperature control system. Because we accept customer’s customization, we will rationally design the appearance of each plate according to the customer’s use site. Such as the size of the equipment, the position and size of the inlet and outlet, and the installation height. Industrial temperature control equipment will not be miniature, and its length, width and height are definitely higher than that of an adult. Secondly, the pipeline of cooling water circulating water needs to be informed of the working conditions on site, so that the size and position of the inlet and outlet and the data interface area can be determined before production. Normally, the medium inlet and outlet of our equipment is located on the left side of the rear of the equipment, the pressure gauge is located under the left side of the rear, and the data interface is located under the front color control screen. You can take a closer look at the actual appearance of the device.

Related recommendations

-

How to Carry On Industrial Low Temperature Chillerstest Of Choosing The Better Company?

1614No matter what chillers are used, we need to constantly learn about the relevant knowledge of the industrial-low temperature chillers. Which company's low - temperature chiller is better? Let me tell you, in order to help you to use the industrial...

View details -

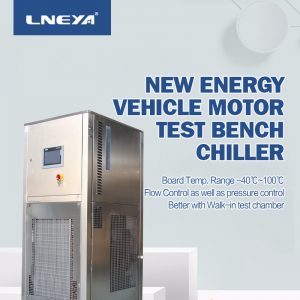

Electric Vehicle Motor Test Cooling System Chiller Instructions

2001With the continuous development of new energy vehicles, Chiller, the electric motor motor test cooling system, is also developing. The new chiller for motor testing of new energy vehicles can adaptively adjust the chiller according to the dynamic ...

View details -

How to reduce the condensing pressure of the heating circulator unit?

1812During the operation of the heating circulator unit, the temperature change inside the equipment will cause the condensing pressure to change. Especially in summer when the condensing pressure is too high, the power consumption of the compressor w...

View details -

Hybrid car battery test equipment cooling capacity description

1556Due to insufficient insulation thickness of the hybrid vehicle battery test equipment and pipeline or damage to the insulation layer, the loss of cooling capacity is increased, which affects the cooling effect. In the operation of the hybrid vehic...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier