Titanium reactor temperature control in daily chemical, pharmaceutical and chemical industries

The advantages and trends of titanium reactors in the daily chemical and pharmaceutical industries, titanium reactors will play a huge advantage in the future. Reaction equipment used to complete processes such as sulfonation, nitration, hydrogenation, alkylation, polymerization, condensation, and many other processes of organic dyes and intermediates. It has excellent properties such as super corrosion resistance, non-magnetic, high temperature resistance, pressure resistance, and bio-affinity.

The titanium reactor needs special attention during operation, otherwise it is prone to damage and causes unnecessary production stoppage. The chemical industry uses a large number of titanium reactors. Due to the corrosiveness of the medium, the hot and cold reaction conditions, transportation, use, and human-made problems, the enamel layer is easily damaged and affects the entire production. If a large area falls off, it needs to be returned to the factory for a new one. enamel.

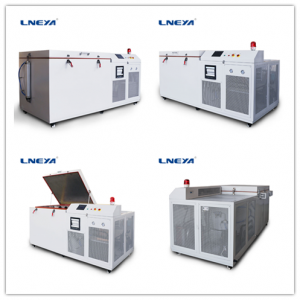

The temperature of the reaction body in the kettle should be cooled at 110 degrees, and the temperature difference between the temperature medium and the reactor should not exceed 90 degrees to avoid cold shock damage to the equipment. This requires the use of high-precision temperature control equipment. Our LNEYA heating and cooling circulators are suitable for temperature control of most reactors.

The structure of the reactor is basically the same. In addition to the reactor body, there are transmission devices, stirring and heating (or cooling) devices, etc. Thus, the reaction temperature can be uniformly controlled. The temperature control of the reactor depends on the temperature change of the heat transfer oil in the jacket of the reactor to control the temperature in the reactor.

The heating, cooling, and temperature control systems of the reactor are sealed, no oil mist is produced at high temperature, and no water vapor is absorbed at low temperature. It is a heat transfer medium that can control the temperature of -100-200 degrees and the cooling capacity of 1kW-80kW in the same machine.

Closed liquid circulation system with expansion vessel. The expansion vessel is insulated from the liquid circulation and is only connected to the machinery and does not participate in the liquid circulation. Regardless of the temperature in the liquid circuit, the medium in the expansion vessel is below 60°C.

The working principle of our LNEYA dynamic temperature control system SUNDI series equipment is like this, and it is the best choice in the reaction vessel temperature control system in the industry.

Related recommendations

-

Temperature conditions of new energy vehicle batteries

853When automobile manufacturers continue to improve battery life to overcome the driver's mileage anxiety, the energy density of the large batteries installed is also gradually increasing, which means that the temperature monitoring function of the...

View details -

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1050Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

View details -

Maintenance of Top 10 Industrial Freezers

1169When we choose and buy industrial freezers of top 10 brands, in addition to some necessary needs, we should also pay attention to the use and maintenance of the industrial freezer, we should select industrial freezers with long service life, high ...

View details -

Heat transfer oil secondary circulation system use instructions

915The thermal oil secondary circulation system is equipped with various instruments and equipment for temperature control. When using it, you need to pay attention to its safety knowledge and safer operation. LNEYA heat transfer oil secondary circul...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier