Temperature control of dynamic temperature control system in process engineering

In the chemical industry, especially in process engineering, many processes are bound to a temperature, or can be supported by specific temperature control applications, thereby making efficiency higher. An example of the latter is continuous temperature control of the casting medium. In order to maintain the necessary viscosity, in addition to the storage tank, the material pipe, pump and metering unit can also be heated. The optimal temperature control of the casting material during the entire process not only makes the processing process easier and faster, but also simplifies the rise and discharge of inclusions, thereby reducing production time and scrap rate, and improving quality. The temperature control system used must be able to react quickly and continuously to change and stabilize the process.

However, the dynamic compensation of exothermic or endothermic chemical reactions poses greater challenges to the temperature control system. Especially if the reaction occurs in an extreme temperature range, the temperature control system must provide fast compensation. This not only ensures effective and consistent results, but also ensures the safety of the process.

From laboratory benchmarks to large factories

The requirements of the temperature control system also depend on its scope of application. When developing new programs in the laboratory, not only the performance and response speed, but also the wide operating temperature range and simple and flexible changes between applications are of decisive importance for the choice of temperature control system. Therefore, the temperature control system can be used in a variety of applications without any problems. The size and mobility of the equipment, water or air cooling, and the precise positioning of connections and vents are decisive for the applicability of the temperature control system in daily practical use. In large industrial applications, consistent performance, low maintenance requirements and high energy efficiency are the main focus. Since these units are usually only used for temperature control of a single process, a lower dynamic range may be sufficient.

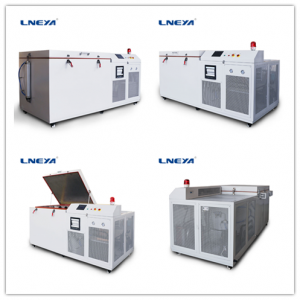

Typical applications of dynamic temperature control systems: dynamic constant temperature control of various types of reactor cold and heat sources, constant temperature control of micro-channel reactors; low temperature and high temperature aging test of materials, constant temperature control of chemical cold source and heat source combination, cooling and heating control of semiconductor equipment, etc. The temperature range is -120 ℃ to 350 ℃, with superior performance, high precision and intelligent temperature control. Compared with other thermal control systems, dynamic temperature control systems sometimes have very different thermodynamic characteristics. In fact, the dynamic temperature control system has obvious advantages in your process: significantly shortens the heating and cooling time, and has better stability and repeatability in the entire process chain. For expensive glass reactors and contained The substance has higher safety and easy operation.

Related recommendations

-

What is the refrigeration principle of the glycol chiller system

1906Glycol Chiller System , as we can tell fromits name, it is to use Glycol as the refrigeration agent for the chiller. In the all air environment, because of thelow temperature in the outdoors, it is impossible to use a cooling tower tosupply t...

View details -

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1658Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

View details -

How To Choose the Ultra Low Temperature Recirculating Chiller Expansion Valve?

1535Selection and installation of the expansion valve for ultra low temperature recirculating chillers: the selection of expansion valve plays an important role in the performance of the ultra low temperature recirculating chiller refrigeration system...

View details -

How to choose a cooling bath and maintenance points

1551The so-called refrigeration thermostat, as its name suggests, is a device that provides a constant temperature. In general, everyone also calls it an incubator, a thermostat, and so on. Only know enough to use the cooling bath better. Refrigeratio...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier