Installation and maintenance of industrial water chiller

As a industrial temperature control device,

industrial water chiller is often in 24-hour operation. Therefore, it is very

important to choose a industrial chiller with good performance. Wuxi Guanya

Refrigeration Technology Co., Ltd. specializes in the manufacturing, research,

development, production and sales of industrial temperature control equipment

such as industrial water chiller and ultra-low temperature chiller. 15 years of

concentration and experience have made LNEYA’s industrial water chiller a

leader in the industry. LNEYA specializes in providing customers with cooling

and heating temperature control solutions, and meets customers’ temperature

needs with superior performance industrial water chiller. In order to maximize

the service life of the industrial water chiller, we need to know the following

installation and maintenance methods in daily use.

Installation precautions: the installation

site of the industrial water chiller must be the floor or installation mat, and

can bear the operating weight of the chiller. It should be placed in a machine

room with a room temperature of 4.4~43.3℃, and sufficient space shall be

reserved around and above the industrial water chiller for daily maintenance.

When the water source and the surrounding environment of the cooling water

tower are bad, the cooling water circuit must be equipped with a Y-type filter

and cleaned regularly. Choose the matching cooling tower according to the

refrigeration capacity of the industrial water chiller. After the chilled water

piping system passes the leak test, it is necessary to wrap the insulation

layer to avoid cooling loss and dripping of the pipeline.

Maintenance method: If the industrial water

chiller has been used for more than 6 months, and refrigeration capacity is

reduced, please arrange staff to clean the radiator. If the industrial water

chiller is equipped with a pressure gauge, check whether the pressure of the

high pressure gauge is higher than 300PSI. If it exceeds, please clean the

radiator or check whether the water hose has been fully opened. The repair is

carried out according to the above operation for several times, but the alarm

signal of industrial water chiller failure is still ringing, please arrange

staff to repair it. After the chiller is out of service for a period of time,

the water pump blade may be solidified due to the water dirt. When starting up

again, the water pump rotor must be loosened first to avoid that the pump blade

does not rotate and burn the motor.

Related recommendations

-

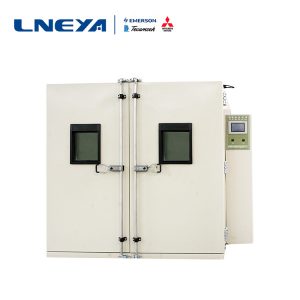

Description of the characteristics of the LNEYA walk-in test chamber

872Wide temperature control range can meet the user's various needs.Unique balanced temperature control method, a stable and balanced heating capacity can be used for high precision and high stable temperature control.The temperature displayed by tou...

View details -

How to use industrial water chiller to reduce environmental pollution

810With the continuous development of chemicaland pharmaceutical industries, environmental pollution is put on the agendaearlier. As an manufacturer of which is the industrial water chiller, I can saythat except for corresponding to the environmen...

View details -

Reactor temperature control unit TCU with PID control loop

1150LNEYA reaction kettle temperature control unit tcu adopts PID control loop, which has certain applications in many fields. The reaction kettle temperature control unit tcu of PID control loop adopts fully closed cycle refrigeration system, with fa...

View details -

Operation instructions for cooling and heating system of reactor

1105The reactor cold and hot switching integrated machine is a cooling and heating temperature control equipment applied in various industries. How much do you know about the reactor cold and hot switching integrated machine? In the pharmaceutical, ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier