How to use industrial water chiller to reduce environmental pollution

With the continuous development of chemical

and pharmaceutical industries, environmental pollution is put on the agenda

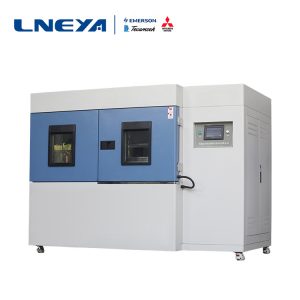

earlier. As an manufacturer of which is the industrial water chiller, I can say

that except for corresponding to the environmental protection theme, Our LNEYA

circulating water chillers use environmentally friendly materials and

refrigerants,increasing the efficiency constantly.

Industrial chiller units lower the

condensing temperature in the conditions of evaporating temperature, and increase

the vaporization point and reduce the condensation temperature as much as

possible when meeting the requirement of safety and manufacture, ensuring the

cooling water efficiency and enlarging the change of cooling tower.

I should tell you that for the sake of

ensuring the industrial water chiller to operate safely, the power dissipation

of a number of cold energies is smaller. It should consider the operating

situations of the water pump and cooling tower comprehensively while taking

this method into effect.

To prevent and reduce the pipe scaling of

industrial water chiller is for enhancing the heat transfer efficiency of the

condenser and evaporator. If the make-up water is treated badly, calcium

carbonate and magnesium carbonate produced by calcium bicarbonate and magnesium

bicarbonate through heating will precipitate on the pipes, decreasing the

heat-conducting property to have an impact on the heat exchange efficiency of

condenser and evaporator and increase the electric charge by a large margin for

chiller’s operation. Apart from using water treatment technology, that you can

apply the equipment for cleaning the pipes regularly, which can save the

electric quantity and at the same time level up cooling-water machine’s effect.

When centrifugal refrigeration machine’s

compressor is adjusted by the frequency converter of industrial water chiller

on account of revolving speed, the pressure will be raised as low-tension

refrigerant goes through hydroextractor. The faster the rotational speed is,

the higher the pressure is. In actual operation, the equipment works without a

full load. The centrifugal machine with fixed revolving speed operating in

small load will waste the energy.

When mastering the four points mentioned

above, I am sure the working efficiency will be improved better. It is

necessary to follow these steps so as to protect the environment!

Related recommendations

-

How will the battery be affected when the fuel cell vehicle starts cold at low temperature?

1651At present, the topic of fuel cell vehicles in China is relatively hot. Fuel cell vehicles have the advantages of large market space, high technological status, short hydrogenation time, high battery life, and low pollution. However, at present, f...

View details -

Use of cold processing refrigerators for mechanical parts and comparison with liquid nitrogen

1475In the machinery manufacturing industry, the quality requirements for parts are very strict. In order to better improve the performance of machinery, improve product quality and life, a new technology-cryogenic treatment has been produced. During ...

View details -

Analysis of Advantages and Disadvantages of Screw Water Chiller

1935Compared with other types of chillers, the overall energy consumption of high-quality screw water chiller is relatively small. Because the production technology of screw water chiller is more advanced and less energy is used, the equipment can qui...

View details -

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1750The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier