Cooling water circulator for BMS testing of liquid-cooled battery packs

As the weather temperature gradually increases, the use of liquid-cooled battery pack BMS test cooling water circulators also gradually reaches its peak. Liquid-cooled battery pack BMS test cooling water circulators have rated power ranging from several kilowatts to several kilowatts. Today’s production technology is developing rapidly, and it is more guaranteed in terms of operability and stability. However, the problem that is plagued by many companies is the increasing energy consumption. What is the reason for the liquid-cooled battery pack BMS test cooling water circulator? What about energy consumption? Enterprises need to conduct timely inspections on equipment before they can maintain long-term stable operation of equipment. The following editor and everyone analyze the reasons.

If the equipment is faulty, and the cooling performance of the liquid-cooled battery pack BMS test cooling water circulator continues to decrease, then the enterprise should be cautious when using it. When operating the equipment, once the enterprise ignores the existence of various common faults, although the equipment can be used normally for a while, the operation of the equipment is directly affected. When an enterprise uses a liquid-cooled battery pack BMS to test the cooling water circulator for increasing energy consumption, it means that the equipment failure is very serious and needs to be dealt with in a timely manner, otherwise it will threaten the normal use of the equipment and even cause the company’s test cost to be large The amplitude increases, so the stronger the awareness of the equipment protection, the lower the probability of equipment failure, so as to achieve low energy consumption to run the liquid-cooled battery pack BMS test cooling water circulator.

If the equipment is operated for a long time, and during the process of running the liquid-cooled battery pack BMS test cooling water circulator, the enterprise should also provide sufficient rest time for the equipment, and the enterprise can rationally formulate the liquid-cooled battery pack BMS test cooling water circulator operation Plan, or use multiple liquid-cooled battery packs to test the cooling water circulator, and run different equipment in an alternating manner, which can basically reduce more than half of the expenses and avoid increasing energy consumption. There was a problem.

When an enterprise uses a liquid-cooled battery pack BMS to test a cooling water circulator, if there are many unsuitable factors in the environment, energy consumption will continue to increase. As an enterprise, the main purpose of using the liquid-cooled battery pack BMS to test the cooling water circulator is to quickly achieve the cooling of the test space. When the environment location selected by the device is poor, the operability of the device is directly affected.

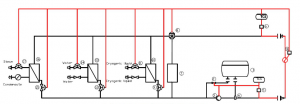

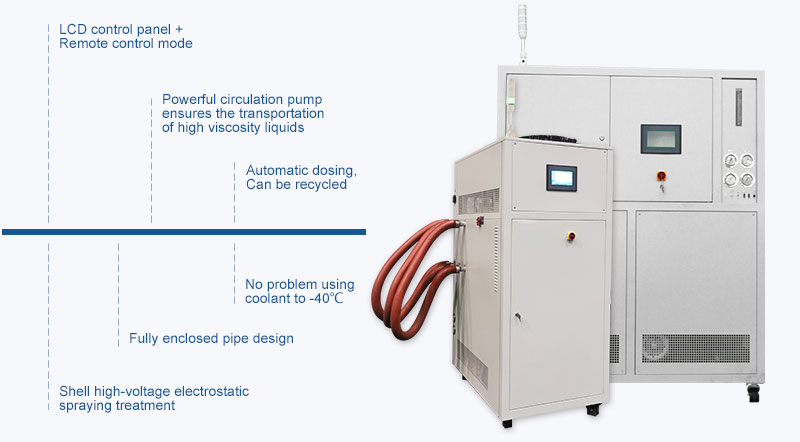

LNEYA liquid-cooled battery pack BMS test cooling water circulator KRY series temperature control range -40 ℃ ~ 100 ℃, the device can be multi-channel temperature and flow control, one device can achieve multi-channel output, each channel can control different flows without interfering with each other . Fully enclosed tube design, high-efficiency plate heat exchanger, used for lifting temperature and constant temperature control in the testing of new energy batteries and motors, especially suitable for the control of heat dissipation and heat release during the test.

Related recommendations

-

How should an industrial chiller manufacturer choose

12252. Try to select well-known brandindustrial chiller manufacturers with technical professional work experience.3. If there are visits and inspections, wemust attach great importance to the big aspects and pay more attention to thesmall key point...

View details -

Chemical synthesis process control system temperature control system TCU

1710Today, let's talk about our DCS integrated control system (temperature and other control of synthetic process). Scalability: the system is an open system, which provides standard TCP / P data communication interface protocol, interface software an...

View details -

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1750The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

View details -

How to control the temperature of the refrigerating heating temperature control system

1896The refrigeration heating temperature control system is matched with the glass reactor as the ideal teaching and experimental temperature control equipment for the synthesis of modern fine chemicals, bio-pharmaceuticals and new materials. For this...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier