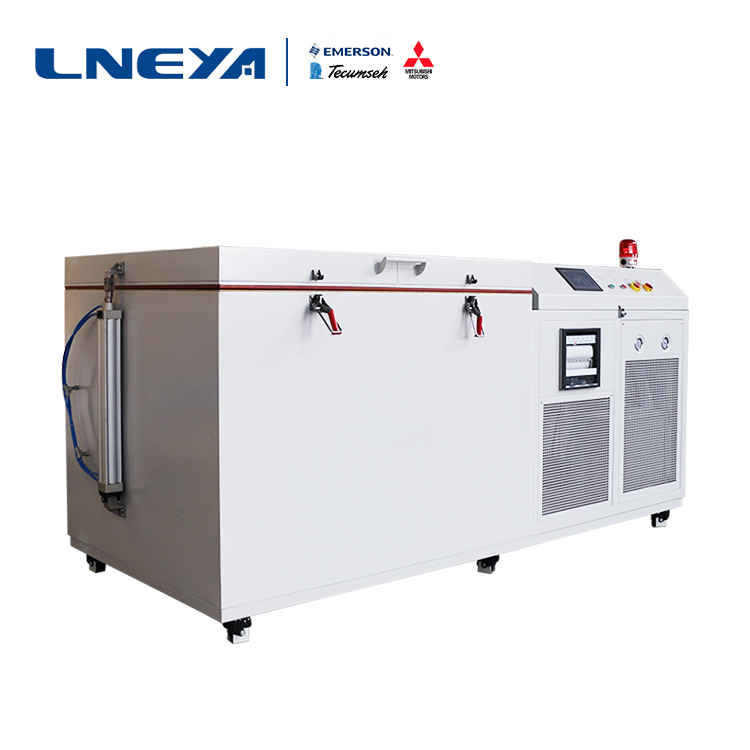

High-power industrial refrigerator evaporator maintenance precautions

High-power industrial refrigerators are used in industrial cold processing. Evaporators in high-power industrial refrigerators are one of the most important components and one of the factors affecting the cooling effect of high-power industrial refrigerators. Then, high-power industrial refrigerators are evaporated. What should I pay attention to during maintenance?

The evaporators in LNEYA high-power industrial refrigerators are generally well-matched in the design of high-power industrial refrigerators. In the case of high-power industrial refrigerators, high-power industrial refrigerator refrigeration systems can be better maintained to ensure efficient operation. Should pay attention to the influence of the liquid level on the evaporation temperature. Due to the influence of the height of the refrigerant liquid column of the high-power industrial refrigerator, the evaporation temperature at the bottom of the full-liquid evaporator is higher than the evaporation temperature of the liquid surface. Different refrigerants, high-power industrial refrigerators are subjected to hydrostatic liquid at different liquid surface evaporation temperatures. The effect of height is different. Regardless of which refrigerant is used, the lower the evaporation temperature of the liquid surface, the greater the effect of the hydrostatic height on the evaporation temperature. Therefore, the effect of the hydrostatic height on the evaporation temperature can be ignored only when the evaporation pressure is high.

The pressure loss of the high-power industrial refrigerator refrigerant in the evaporator is also an important factor. When the refrigerant flows through the evaporator, the pressure loss is caused, and the pressure p2 of the refrigerant at the outlet of the evaporator is inevitably lower than the pressure p1 at the inlet. , thereby reducing the suction pressure of the compressor, resulting in a decrease in refrigeration capacity. According to different high-power industrial refrigerator models, the evaporators of the unit are also different. For example, open high-power industrial refrigerators and screw-type high-power industrial refrigerators, shell-and-tube evaporators; box-type high-power industrial refrigerators. , is the use of water tank coil evaporator; acid and alkali high power industrial refrigerator, can choose titanium tube evaporator or stainless steel plate exchanger; a high-power industrial refrigerator, there are many options, of course, can be based on Customized by user needs.

Power industrial refrigerators require regular maintenance to extend the service life. Therefore, high-power industrial refrigerators need to pay attention to some details when using them to avoid some use failures.

Related recommendations

-

How to Maintain Low Temp Chillers

1433Low temp chiller is a kind of refrigeration mechanical equipment which needs to be used in many industrial production operations. It can provide very good refrigeration technology for different production operations and ensure the smooth progress ...

View details -

Precautions for Leakage Inspection of Glycol Chiller

2199The main points about checking leakage of glycol chillerDuring the operation of the glycol chiller, it is critical that the refrigeration system does not leak. In order to avoid the leakage of refrigerant and other gases from the glycol chiller, ...

View details -

Single cone dryer cooling and heating devices

1176Single cone dryer is a commonly used solid material drying equipment, widely used in chemical, pharmaceutical, food and other industries. In order to ensure temperature control during the drying process, it is usually necessary to equip ...

View details -

How to improve the efficiency of water cooled chillers?

1800Water cooled chiller is a kind of mechanical equipment that uses water resources for refrigeration. In recent years, water-cooled chiller is more and more widely used at home and abroad, mainly because most modern industrial production needs to us...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier