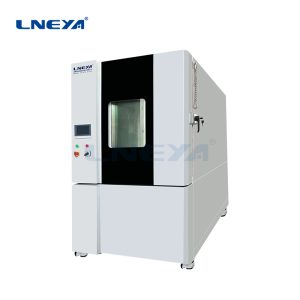

What kind of battery pack test chamber meets the laboratory?

The application of battery pack test chamber in the laboratory needs to meet a series of strict requirements to ensure the accuracy and safety of the test results. These requirements mainly involve the following aspects:

Temperature control range and accuracy: The test chamber should have a wide temperature control range, usually covering low temperature (such as -40°C or lower) to high temperature (such as 85°C or higher), and ensure that the temperature control accuracy is within ±2°C to simulate extreme environmental conditions. The temperature conversion time should be fast and controllable to meet the needs of rapid temperature cycle testing.

Humidity control: For tests that need to simulate specific humidity conditions, the test chamber should be able to provide humidity control function, which is usually required to be adjustable within the range of 10% to 98% RH (relative humidity) and with high control accuracy.

Safety performance: Considering the potential dangers of battery testing, the test chamber must meet the corresponding safety standards, such as explosion-proof design, over-temperature protection, leakage detection and emergency shutdown functions to ensure the safety of operators and laboratories.

Data recording and analysis: The integrated data recording system automatically records key parameters such as temperature, humidity, voltage, current, etc. during the test process, which is convenient for subsequent data analysis and quality traceability.

Durability and maintenance: The test chamber should be made of corrosion-resistant materials, easy to clean and maintain, and ensure long-term stable operation.

Compatibility and customization: The test chamber should be compatible with battery packs of different models and sizes, and also provide a certain degree of customization to meet specific testing needs.

Software control and automation: It has a user-friendly operating interface and automated control software, which can realize the programming, execution and monitoring of test procedures, and improve test efficiency and accuracy.

Standardization and compliance: The design and operation of the test box should comply with relevant industry standards and regulatory requirements, such as GB/T 31486-2015 (Electrical performance requirements and test methods for power batteries for electric vehicles), UN 38.3 (Test requirements for the transportation of dangerous goods), etc.

Environmental adaptability: The laboratory space is limited, and the test box should be compactly designed. At the same time, the power supply and ventilation conditions of the laboratory should be considered to ensure that the equipment can work stably. By meeting the above requirements, the battery pack test box can provide a safe, accurate and efficient testing environment for the laboratory to support research and development work in various aspects such as battery performance evaluation, safety verification, and life prediction.

Test Chambers

Related recommendations

-

Two-box impact test chamber

2303The test basket of the double-chamber cooling and heating shock test chamber is mobile when conducting high and low temperature shock tests. The high and low temperature shock conversion is mainly completed by moving the test baske...

View details -

Why Is Temperature Cycling Testing Performed On Chips?

1370Why Is Temperature Cycling Testing Performed On Chips? Temperature cycling testing is a technique employed to evaluate the durability of semiconductor chips. By repeatedly exposing the chip to alternating high and low temperatures, this test ...

View details -

How Many Types of Test Chambers Are There

870Learn what a test chamber is, how it works, and the types used in product testing. From temperature and humidity chambers to vibration and altitude testing, discover which suits your needs.

View details -

Industrial Freezer GD Series

135APPLICATIONS Mainly used in industrial cold treatment, it makes the uniform, fine and dispersed carbonization produced on the matrix organization of metal structures precipitate. The precipitation of carbides will significantly improve ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier