Why Is Temperature Cycling Testing Performed On Chips?

Temperature cycling testing is a technique employed to evaluate the durability of semiconductor chips. By repeatedly exposing the chip to alternating high and low temperatures, this test simulates how the chip performs under extreme thermal conditions. After reading this blog post, you’ll gain a solid understanding of what temperature cycling testing is, why it matters, how it’s conducted, and the relevant testing standards.

What Is The Temperature Cycling Testing?

Temperature cycling testing is performed during both the product development and screening phases. It is also called thermal cycle test or high-low temperature cycling test. During the test, the sample is exposed to a controlled environment where high and low temperatures alternate in cycles. This process is used to evaluate the product’s durability and reliability under thermal stress.

How To Perform Temperature Cycling Testing?

Temperature Cycling Testing Procedure

Step 1: Place the chip to be tested into the temperature cycling test chamber.

Step 2: Set the high and low temperature range. Typically, the high temperature ranges from +50°C to +150°C, while the low temperature ranges from -10°C to -70°C. These settings can be adjusted based on specific testing requirements.

Step 3: Within the defined temperature range, the test chamber continuously cycles the temperature. For example, the chip may be exposed to high temperature for 12 hours, then to low temperature for another 12 hours, repeating this cycle.

Step 4: Repeat the temperature cycling process until the chip reaches the predetermined number of cycles or fails due to thermal stress.

Technical Parameters of Temperature Cycling Testing

The technical parameters of temperature cycling testing include: high temperature, high-temperature dwell time, cooling rate, low temperature, low-temperature dwell time, heating rate, and the number of cycles. The severity of the test depends on the high/low temperature range, humidity levels, and exposure duration.

According to available data, a minimum of three cycles is required for temperature stabilization. This means that chip-level temperature cycling tests must be conducted at least three times. While stability is typically achieved after three cycles, for better repeatability, it is recommended to perform at least two additional cycles—for a total of five.

When conducting temperature cycling testing, the number of cycles should be selected based on the product’s actual operating environment and reliability requirements. This ensures the results accurately reflect the product’s real-world performance under thermal stress.

Standards of Temperature Cycling Testing

- GB/T 2423.3 – Basic Environmental Testing Procedures for Electrical and Electronic Products: Test Ca – Damp Heat, Steady State

- IEC 60068-2-78 – Environmental Testing for Electrical and Electronic Products: Test Ca – Damp Heat, Steady State

- GB/T 2423.4 – Environmental Testing for Electrical and Electronic Products – Part 2: Test Methods – Test Db: Damp Heat, Cyclic (12 h + 12 h cycle)

- IEC 60068-2-30 – Environmental Testing – Part 2-30: Tests – Test Db and Guidance: Damp Heat, Cyclic

Criteria for Evaluating Temperature Cycling Testing Results

- The product surface must be free from damage, deformation, or other defects. For coated or plated surfaces, there should be no signs of peeling, blistering, or discoloration.

- Plastic components must show no cracks, blistering, or warping.

- Rubber parts must not exhibit aging, stickiness, softening, or cracking.

- Welded joints on product components must not show signs of solder flow or displacement.

- Product performance and structural functionality must meet the specified technical requirements. No other defects should be present that could impair the normal operation of the product.

What Is The Purpose Of The Temperature Cycling Testing?

According to a report by the IES in the United States, among various commonly used environmental tests, the temperature cycling test ranks highest in effectiveness—reaching 77%.

Temperature cycling testing helps evaluate the durability and stability of materials or products under extreme temperature conditions, making it a key method for assessing product quality and reliability. It is a key method for guaranteeing consistent product performance over time.

Final Thoughts

In the fields of evaluating both the durability and reliability of semiconductor chips, temperature cycling testing plays a significant role.

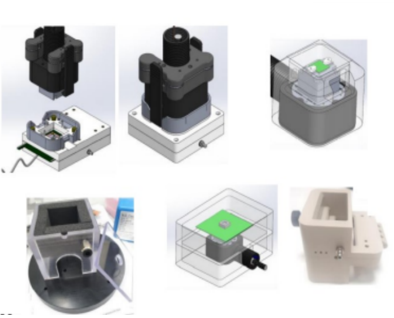

LNEYA environmental test chambers can offer a temperature control range from -80°C to +150°C, fully meeting the requirements for chip-level temperature cycling testing.

WeChat/Phone

86 18914253067

86 13912479193

Email Address

sales@cnzlj.com

Recommended Products

GD -80℃~150℃

climatic test chamber

Heating rate (+20~+150℃)A:5℃/min

Cooling rate Carrying idler (+20~-40℃)5℃/min

GD -40℃~180℃

thermal shock chamber

Low temperature -40~0℃

High temperature +60~+150℃

Temperature fluctuation ≤1℃

LQ -110℃~-40℃

Nitrogen chillers

Gas flow 15m³/h~100m³/h

Circuit breaker 10A~25A

Lowest temperature -40℃/-75℃/-110℃

AES -120℃~225℃

Temperature forcing system

Temperature accuracy ±0.1℃

Air treatment capacity 10m³/h-30m³/h 5bar-7.6bar

Heating and cooling rate <10s

AET -75℃~250℃

Thermal test system

Temp range Gas outlet ± 0.1℃, remote process ± 0.5℃

Air handing 22m³/h~95m³/h

Heating and cooling rate <10s

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier