What are the functions of the reactor temperature control system?

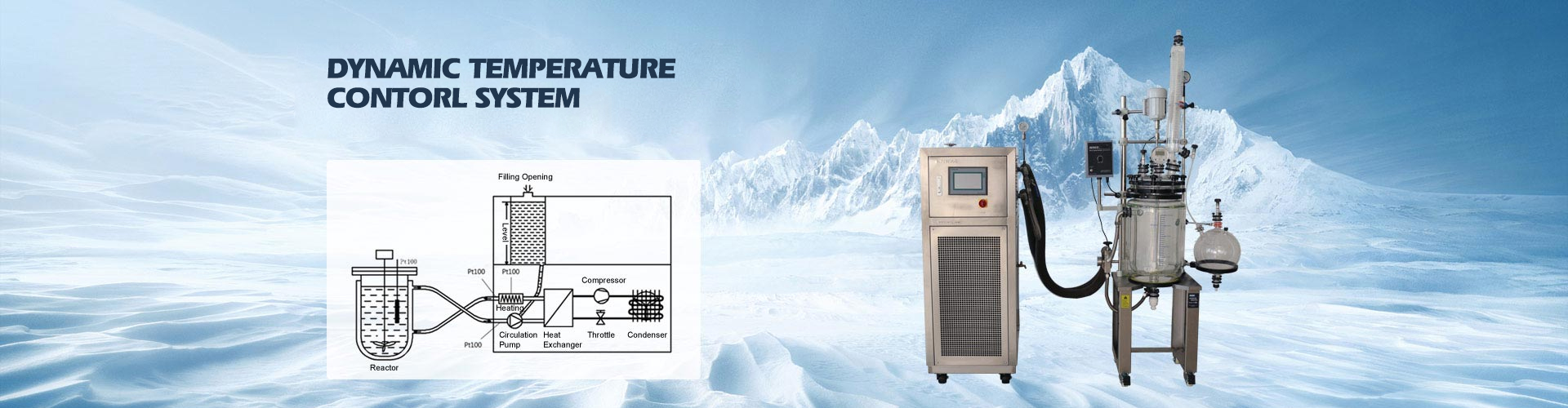

The reactor temperature control system is equipped with various reactors for high and low temperature reflection of liquid and solid. The temperature control system of LNEYA reactor adopts fully closed circulation pipeline, which is efficient in operation and less polluted. So, what are the advantages of the reactor temperature control system?

LNEYA applies the technology to the reactor temperature control equipment, which can dynamically display the operating status of each equipment in real time, including real-time data changes of raw material tank weight, feed rate of various materials, valve operation on the equipment and corresponding temperature. The data display, etc., can simulate the flow chart shape, and the image is intuitive and easy to read.

The reactor temperature control system can display the real-time curve and historical data curve of each process parameter, and compare with the set process curve to guide the production process. The displayed historical curve can be saved for more than one year, which is convenient for users to view at any time. With the various process curves and ratios of the memory in the system, it is possible to issue control requirements to the PLC at any time according to the requirements of the production process, so that the production variety and the rapid change of the production process can be completed.

In addition, the reactor temperature control system can print a variety of production and statistical reports, with a very strong management function, the actual weight of each batch and the corresponding temperature, pressure data, etc., to print the data cost Accounting. The LNEYA autoclave automatic control system can perform manual and automatic interference-free switching operations. In order to enhance the performance of the whole system without losing flexibility, the system is equipped with computer operation and can be operated by touch screen, whether manual or not. Automatic or console button operation can be implemented very conveniently.

The reactor temperature control system uses an intelligent control technology to dynamically adjust the temperature by automatically adjusting the multi-parameters of the reactor jacket cooling water and material feed rate, thus allowing various physical processes and The chemical reaction process is more efficiently controlled.

The LNEYA reactor temperature control system uses a complete safety protection device to ensure safety problems in the production process of the reactor temperature control system to a greater extent.

(This article source network, if there is infringement, please contact LNEYA to delete, thank you.)

Related recommendations

-

Protection device details of circulating fluid temperature control device

1149The circulating pump overload protection function is to cut off the main power of the circulating pump when the circulating liquid temperature adjustment device is too large. Press the green button when resetting; the red button is the stop button...

View details -

Explosion-proof cryogenic refrigeration unit icing, do you know what is going on?

1284When using an explosion-proof cryogenic refrigeration unit, many users do not know how to solve the problem of icing and frosting. In fact, the professional can tell you with certainty, no. The two causes are different, so the processing method is...

View details -

Cooling and heating system TES for integrated circuit wafer cooling method

1091Integrated circuit products have been developed for more than 50 years and are the most advanced high-tech industries. Integrated circuit or chip / chip. The complete chip manufacturing process includes chip design, wafer manufacturing, package ma...

View details -

Configuration form of circulating heating unit for laboratory

925The standard model of the circulating heating unit for LNEYA laboratory is: SUNDI, the temperature range is from room temperature to minus 120 degrees Celsius, and the capacity can be divided into 5L, 10L, 20L, 30L, 40L, 50L, 80L, 100L, larger cap...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier