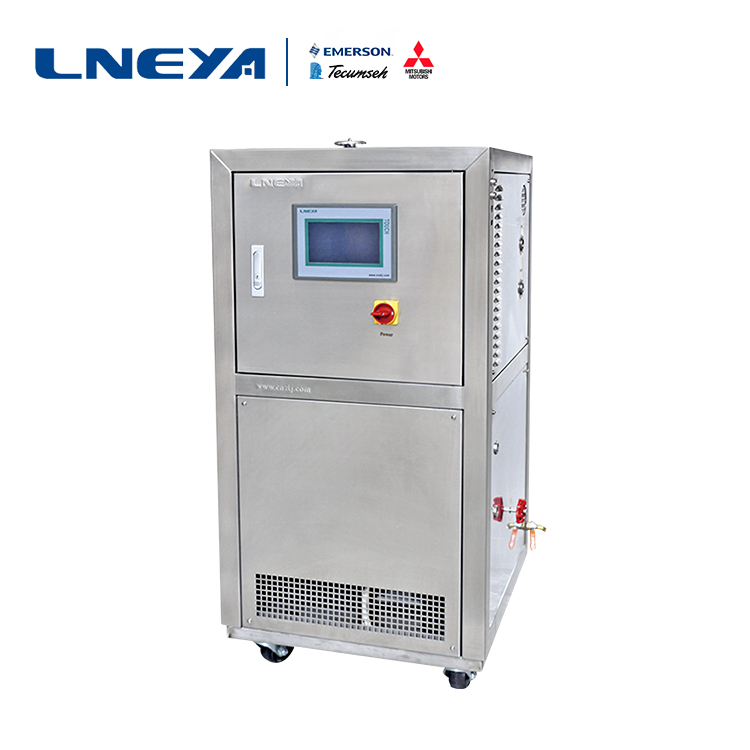

5P hot and cold water machine installation instructions

The 5P hot and cold water machine is used in various industries and is used for cold treatment. So what problems do you need during installation and maintenance?

If the 5P hot and cold water unit refrigeration compressor unit does not have vibration reduction installation, or the vibration reduction effect is not good, according to the installation specifications, the overall vibration damping device should be installed. If the vibration reduction is not standardized or there is no vibration reduction measure, the machine will vibrate severely. It is easy to cause the pipe to crack, 5P hot and cold water machine equipment is damaged, and even other equipment is damaged.

There is no or lack of oil return bend in the refrigerant line of the 5 hot and cold water integrated machines. When the pipeline conveying the refrigerant turns upward from the lateral direction, it must be made into a small bend that is first down and then upwards, that is, a U-bend, so that the 5P hot and cold water integrated machine pipelines are qualified only upwards, and cannot be directly Make a 90 degree steering upward, otherwise the oil in the system can not be returned to the compressor very well, and a large amount of deposition in the equipment, so that 5P hot and cold water machine and the entire system can not function properly, or even damage the equipment .

5P hot and cold water machine integrated machine refrigerant pipeline connection is not balanced, when the unit pipeline is connected to a group of multiple compressors, to make the oil return equal distribution to each compressor, the main pipeline interface must be set at multiple stations. In the middle position of the machine head, then set some branch lines to the two sides to balance the return oil into multiple compressor branch pipes.

The models and designs of the 5P hot and cold water machines of different manufacturers are different. When the LNEYA equipment is issued, the corresponding instruction manual will be attached to give the customer a detailed explanation.

Related recommendations

-

Lneya Semiconductor High Precision Temperature Control System Description

1998Semiconductor high-precision temperature control systems are currently produced in the semiconductor industry with highly complex performance. Here is a description of the semiconductor high-precision temperature control system. Along with large-s...

View details -

Summary of Maintenance Items of Glycol Chiller

1662During the daily operation of glycol chiller, if the maintenance is not in place, the cooling effect of glycol chiller will be reduced. Therefore, in order to improve the operation efficiency of glycol chiller, we suggest that you should carry out...

View details -

Precautions for the use of molecular distillation cooling and heating temperature control

1454The SUNDI series of LNEYA refrigeration and heating temperature control system are used together to control the temperature in the process of molecular distillation. What should be paid attention to in use? If the molecular distillation method ca...

View details -

Closed cycle heating system temperature deviation description

1481If the temperature deviation occurs in the closed cycle heating system during use, it is necessary to check to see if there is any problem in each link, and solve the problem in time. In the steady state, the closed loop heating system displays th...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier