Metal stamping cold treatment

Product data download

Product Description

The cryogenic process can improve the performance of metal materials. Effective and economical technical indicators. During the cryogenic process of martensite, the residual austenite is transformed, and the performance of the finely dispersed carbides in the material changes, which can hinder the movement of dislocations. The ultra-fine carbides strengthen the matrix structure and play the role of grain boundary strengthening, and the following three aspects are improved: impact toughness, wear resistance, and dimensional stability.

In the industry, the treatment method of further cooling the material after ordinary heat treatment to 100 ℃ ~ 196 ℃ is called cryogenic treatment, which can reduce the content of paralympics, promote the precipitation of fine carbides, reduce intercrystalline tensile stress, and thus improve the following macroscopic properties :

Increase hardness: High-speed steel and die steel increase Rockwell hardness by 1 to 2 degrees.

Improve wear resistance: Cr12MoV steel wear resistance increased by 30%, 20Ni3Mo carburized steel wear resistance increased by 89%.

Increased bending strength: The bending strength of 440A cast stainless steel increased from 1135MPa to 1355MPa.

Improve toughness: W6Mo5Cr4V2 impact energy increased from 18J to 40J.

Improve Red Hardness: The hardness of W18Cr4V increases from Rockwell hardness 57.9 to 63.9 at 625 ℃.

Improve dimensional stability: 95Crl8 stainless steel residual austenite is reduced from 35% to 10%.

Improve conductivity: The resistivity of copper alloy Cu-15Ni-8Sn decreases from 2 86 × l0-7 Ω.m to 1.5l × l0-7Ω.m.

With the development of low-temperature technology and the improvement of test methods, people have gradually deepened the research of cryogenic treatment. The research scope has now extended from iron making to powder metallurgy, copper alloy, aluminum alloy and other non-metallic materials. Cryogenic chamber application industries are found in many fields such as aerospace, hardware, tools, molds, friction parts, precision machining, measuring tools, textiles, and automobiles. Cryogenic technology is currently a high-tech to improve the performance of metal materials.

It is characterized by consumables, low power consumption and no environmental pollution. It is a new type of environmental protection technology.

At present, this technology has been widely used in aerospace, marine, military, manufacturing, automotive, hardware tools, sports equipment and other industries.

You may also be interested in these products

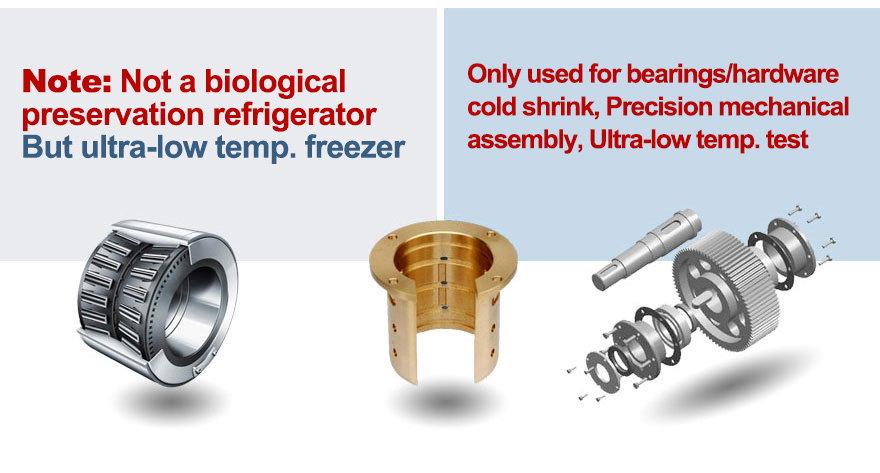

Low Temperature Freezer GD series -150℃

Mainly used in industrial cold treatment, for cold shrinkage of copper sleeves, bearings, precision mechanical assembly, and ultra-low temperature testing. …

Ultra-low Temperature Freezer -80℃~-10℃

Applied in ultra-low temperature testing of large-scale equipment Depending on the on-site environment, you can choose to open the door upwards or sideways, with capacities ranging from 280 to…

Cryogenic Refrigerator -65℃~-10℃

Applied in ultra-low temperature testing of large-scale equipment Ultra-low temperature refrigerator is also known as cryopreservation box, cryogenic refrigerator, cryopreservation box and so on, the common low temp…

Industrial Refrigerator -100℃~-30℃

Ultra-low temperature refrigerator is also known as cryopreservation box, cryogenic refrigerator, cryopreservation box and so on, the common low temperature refrigerator of which is -65 ℃ ~ -10℃. The refrigeration syste…

loading…

已经是到最后一篇内容了!

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier