Top 5 Industries That Rely on Chillers During Hot Summers

High temperatures in summer can bring huge challenges to some industries. As an important temperature control device, chillers play an important role in industrial production. The demand for chillers in temperature-sensitive industries will increase significantly in summer. This article describes the five industries that rely most on chillers, introduces their usage scenarios and needs, and helps you determine whether you need to introduce or optimize cooling solutions.

2. Plastic injection molding and blow molding

The manufacturing of plastic products requires the process of heating and melting plastic particles, injecting them into the mold, and cooling the mold to remove the products. The cooling rate and temperature uniformity of the mold largely determine the injection molding cycle and product quality. Uneven cooling or untimely cooling will lead to quality defects. In addition, the injection molding machine will generate high heat during operation.

If it is not handled in time, it may cause overheating and shutdown, affecting production progress, and even expensive repair bills due to damage. In summer, the mold cooling time will increase and the machine’s heat dissipation effect will also decrease. If you rely on natural cooling, the production cycle will be lengthened, resulting in a decrease in production capacity. Injection molding chillers are an ideal choice for most plastic companies. It supports independent control of the temperature of multiple molds and is very suitable for multi-mold production workshops.

Chip and wafer processing belong to precision manufacturing. Modern chip manufacturing processes have entered the nanometer level and are extremely sensitive to environmental factors such as temperature, particles, vibration, and electromagnetic interference. In the process of lithography, etching, chemical mechanical polishing, ion implantation, etc., any small temperature fluctuations may cause thermal expansion and contraction, which may lead to a decrease in yield.

Moreover, high-energy ion beam equipment, laser exposure systems, vacuum chambers and other equipment generate a lot of heat inside, and chillers are needed to help maintain constant temperature operation. The ambient temperature rises in summer, and the temperature control pressure of the machine room and clean room increases.

If the cooling system is unstable, equipment damage, production suspension, and increased product scrapping rates may occur. Many semiconductor companies have found that the use of high-precision semiconductor chillers can help cool precision equipment and control the temperature of the process flow. It not only improves the yield rate, but also extends the service life of the equipment.

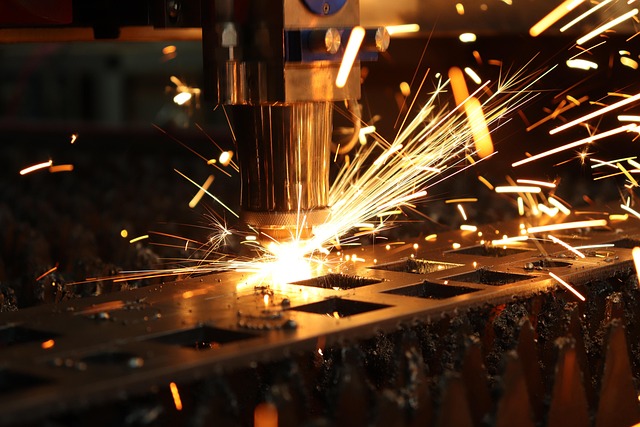

Laser equipment is widely used in metal cutting, welding, marking, engraving, communications and other fields. The laser releases a lot of heat during operation, and its heat generation is proportional to the power. If the cooling is not timely, problems such as thermal drift, output energy decline, and beam divergence are prone to occur, resulting in product quality problems such as material burning, uneven edge melting, and rough welds.

When the heat accumulates too much, it will trigger a high temperature protection shutdown or even damage the equipment. The laser chiller can cool the core part of the laser, keep the focusing accuracy and optical path stable, and improve the yield rate.

MRI, CT, laser surgical instruments and other equipment will generate a lot of heat during operation, which affects the accuracy of operation and increases the risk of damage. For the pharmaceutical industry, precise temperature control is required for reactions, fermentation, crystallization, distillation and other links in the drug production process to ensure reaction stability, safety and finished product efficacy.

Poor natural heat dissipation of medical equipment in summer can easily affect diagnostic efficiency and cause overheating and shutdown. Temperature fluctuations caused by high temperatures in the pharmaceutical process may cause the raw materials to be scrapped. Medical chillers are often used to cool medical equipment and provide a precise reaction environment for glass reactors and jacket cooling systems.

5. Printing and packaging

Printing and packaging involve heat-intensive processes such as offset printing, UV curing, thermal transfer, and sealing. Equipment generates heat during continuous operation, and key parts like rollers, motors, control boards, and UV lamps may overheat without proper cooling—causing system alarms or automatic shutdowns. High ambient temperatures also accelerate ink drying, leading to uneven colors, registration errors, or print defects.

In UV printing, if the lamp housing isn’t cooled in time, printed materials may bubble or warp. Industrial chillers remove heat from UV lamps, preventing overheating and extending lamp life. They also support mold cooling in sealing, forming, or blistering processes, improving forming accuracy and product quality.

Conclusion

Summer is here and the temperature is still rising. It’s time to choose the right industrial cooling system for your equipment and process. LNEYA provides fast delivery, allowing you to install and use it before the temperature peaks. Contact us for the best solution.

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier