How Chiller Failure Affects Productivity

Chiller failure not only affects its own operation, but also affects processes that rely on temperature control. If the abnormality is not handled in time, it may even damage the equipment or increase the risk of accidents.

Deterioration of product quality

The most direct consequence of chiller breakdown is temperature loss. In many process flows, temperature is a key factor in determining the reaction rate of substances and the consistency of finished products. Slight temperature changes may also lead to inconsistent quality between production batches, increase quality inspection and rework costs, and even face complaints and order cancellations.

In the injection molding industry, excessively high or large fluctuations in mold temperature can cause plastic products to deform, shrink unevenly, and bubble or whiten on the surface. In the semiconductor field, processes such as lithography and etching usually require a constant temperature environment. When the temperature fluctuates by more than ±0.1℃, it may cause chip circuit accuracy errors and reduced yields. In the pharmaceutical industry, unstable temperature control of the reactor will result in substandard active ingredients in the drug, or even the entire batch will be scrapped.

Shortened equipment life

A chiller relies on the coordinated operation of multiple components.Any abnormality in any component will affect the overall operating efficiency. If it is operated in a faulty state for a long time, the life of the equipment will be greatly shortened. Frequent start and stop of the compressor or running under high load will accelerate wear.

Abnormal condensing pressure will cause an imbalance in the gas-liquid ratio of the refrigerant, affect system efficiency, and aggravate the wear of the expansion valve. Electronic components such as inverters, thermostats, and control panels will age prematurely if they are often in high temperature, high humidity, and high vibration environments. Chiller failures often start from a certain component, and any minor failure cannot be ignored.

Increased risk of accidents

The chiller contains electrical components, and some equipment uses flammable or toxic refrigerants. If a failure occurs, it may bring safety hazards. If a chiller using R22 or R410A refrigerants leaks, it may cause indoor air pollution and even suffocation risks.

If the high-pressure system is not inspected for a long time, it may cause equipment fire, electrical short circuit and other safety accidents due to pipeline bursting and electronic control failure. Failure of the cooling system of medical equipment may affect the safety of surgery and bring both legal and reputation risks. Especially in old models without safety devices such as high temperature protection, compressor protection, and condensing pressure alarm, the risk of accidents caused by failure is higher.

Increased maintenance costs

If the chiller continues to operate after a failure and the problem is not handled in time, it will cause chain damage and increase the cost of overall maintenance and replacement of spare parts. High-temperature operation will accelerate the deterioration of the compressor lubricating oil, causing serious failures such as cylinder jamming and burning, resulting in the replacement of the entire machine or core components.

If the condenser and evaporator continue to operate after being blocked, it will trigger a high-pressure alarm and system overload. Long-term high-load operation will damage the electronic control system, pumps and other components. Some faults such as water pump leakage, motor overheating, refrigerant leakage, etc., if ignored for a long time, will affect the operation of the entire system and bring large maintenance expenses. Moreover, once failures occur frequently, the company needs to invest in backup units and increase O&M(operation & maintenance)staffing, which increases long-term operating costs.

Interruption of production process

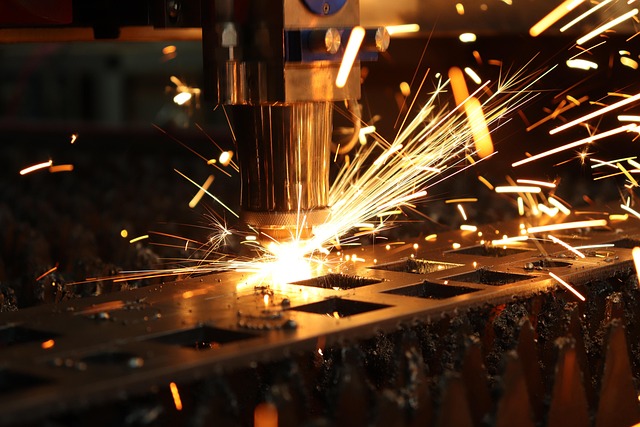

After the chiller fails, processes that require strict temperature conditions and equipment that is sensitive to temperature cannot operate. This will slow down production progress, may delay delivery, and affect the company’s reputation. The laser cutting machine is not supported by a cooling system, and will accumulate a lot of heat.

If the temperature is too high, it will trigger the overheat protection and automatically shut down. In severe cases, it may also damage the light source. Without proper temperature regulation in reactors and fermentation tanks will affect the quality of drugs and production efficiency, and they must wait for the temperature control system to be repaired before resuming work. If an environmental test chamber used in a laboratory or R&D environment fails, the experiment will be interrupted or failed.

How to avoid chiller failure?

In order to avoid chiller failure and ensure that the equipment can still operate stably during production peak or high temperature environment, the appropriate model should be selected according to the working conditions before procurement, and the equipment should be purchased from a reliable supplier.

After being put into use, regularly maintain key components, clean dust and dirt, and check the operating status of the system. Strictly follow the operating instructions and the recommendations of the chiller manufacturer during operation. If the equipment stops due to a fault, the alarm record and operating data should be checked in time and the abnormality should be handled.

Conclusion

The basis for reducing the failure rate of chillers is to purchase a reliable industrial chiller system from a trustworthy chiller manufacturer. LNEYA has been focusing on industrial precision temperature control for 15 years, with rich industry experience and mature temperature control technology, and provides a variety of cooling solutions from standard to customized. If you are facing temperature control challenges, please contact us and we will tailor a stable and safe chiller system for your application.

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier