Comprehensive guide to industrial chillers that you need to know

We utilize advanced refrigeration technologies—including cascade refrigeration, secondary subcooling, and ultra-high temperature cooling—to ensure both production efficiency and safety throughout your operations, even under extreme heat conditions. These technologies enable fast and direct cooling, helping you maintain stable performance during demanding processes.

Additionally, this article provides you with an introductory overview of industrial chillers. You can use it as a reference to help select the most suitable chiller for your specific application.

What is an industrial chiller&chiller application?

Industrial chillers are primarily used for cooling equipment and processes during industrial manufacturing. With their wide temperature control range, precise temperature regulation, rapid cooling capabilities, and energy efficiency, industrial chillers are the ideal solution for enhancing production efficiency, reducing operational costs, improving product quality, and minimizing downtime.

Industrial chillers play a crucial supporting role across various industries, including:

Plastics Industry

Industrial chillers enable precise temperature control during plastic manufacturing and processing. They help improve molding efficiency, enhance product quality, and shorten production cycles.

Food Industry

In the food sector, chillers are essential in production, storage, and transportation. They enhance product taste, ensure consistent quality, and extend shelf life.

Machinery and Equipment

Industrial equipment generates significant heat during operation. Excessive temperatures can reduce production efficiency and cause irreversible damage to machinery—leading to costly repairs. Our industrial chillers help lower equipment temperatures, preventing failures and ensuring smooth operation.

Chemical and Pharmaceutical Industries

Both chemical production and pharmaceutical manufacturing involve exothermic reactions and require strict temperature conditions. Industrial chillers play a vital role in maintaining safe reaction conditions, preventing runaway reactions, and ensuring operational safety in chemical plants. In pharmaceutical processes, chillers are crucial for maintaining efficiency, consistent quality, and repeatable results.

In summary, if your industry belongs to manufacturing, chemical, or pharmaceutical sectors, an industrial chiller can significantly boost your productivity, quality, and operational reliability.

Industrial Chiller Working Principle:The Refrigeration Cycle Explained

The cooling process of an industrial chiller is primarily driven by the heat exchange that occurs through the liquefaction and vaporization of a refrigerant. This process relies on the continuous operation of four core components working in a closed cycle:

1. Compressor

The compressor pressurizes the gaseous refrigerant, converting it into a high-pressure, high-temperature gas.

2. Condenser

The condenser transfers the heat of the high-temperature refrigerant gas to the surrounding environment—typically air or water—causing the refrigerant to condense into a high-pressure liquid.

3. Expansion Valve

The expansion valve reduces the pressure of the liquid refrigerant and controls its flow, allowing it to expand and cool down.

4. Evaporator

The evaporator absorbs heat from the surrounding air or water and transfers it to the refrigerant. As the refrigerant absorbs heat, it evaporates into a gas—thus completing the first cooling cycle.

If the target temperature is still not achieved after the first cycle, the vaporized refrigerant re-enters the compressor to begin another round of cooling.

Types of Chiller

Industrial chillers are primarily used for cooling equipment and industrial processes during manufacturing. The goal is to maintain ideal temperature conditions in industrial production, prevent damage to machinery, reduce failure rates, and improve production efficiency.

Classified by Cooling Method

The two types of industrial chillers operate based on the same working principle. The only difference lies in the method of heat dissipation or the type of cooling medium used.

Industrial Air Cooled Chiller

Uses ambient air as the cooling medium. In air cooled chiller systems, fans are typically used with the condenser to draw outside air into the condenser for heat exchange, then discharge the heated air out of the chiller unit.

Industrial Water Cooled Chiller

Uses water as the cooling medium. Compared with the air cooled chiller, it requires a cooling tower for heat dissipation.

Comparison of Water Cooled Chiller and Air Cooled Chiller

- Industrial Air Cooled Chiller

Cooling Medium: Ambient air

Special Equipment: Fan

Water Consumption: Low, no need for continuous water supply from a cooling tower

Application Scenarios: Areas with limited water resources or sub-zero temperatures

Cooling Performance: Suitable for most small to medium-sized scenarios, but not as efficient as water cooled chillers

- Industrial Water Cooled Chiller

Cooling Medium: Water

Special Equipment: Cooling tower, pump

Water Consumption: High, requires continuous water supply from a cooling tower

Application Scenarios: Areas with abundant water resources and temperatures above freezing (cooling towers require a continuous water supply, and water will freeze below 0°C)

Cooling Performance: Suitable for large-scale scenarios, significantly better cooling performance than air cooled chillers

Benefit of Industrial Chillers

High-Efficiency Cooling

By flexibly applying ultra-high temperature cooling technology, secondary subcooling, and cascade refrigeration systems, you can achieve various cooling demands, such as direct cooling from 300°C or rapid temperature drop cooling.

Increased Productivity

Proper use of industrial chillers helps avoid inefficiency due to overheating and reduces downtime caused by equipment failure. Additionally, keeping equipment in good operating condition contributes to higher output of high-quality products.

Reduced Production Risk

In industrial production, equipment and personnel safety are more important than output itself. The powerful cooling capacity of industrial chillers, along with customizable explosion-proof features, provides reliable protection for your production processes.

Flexible Applicability

Different industrial environments have varying requirements for chiller cooling capacity, footprint, cooling methods, and other factors. You don’t need to worry about these issues when choosing an industrial chiller because it can be customized with appropriate accessories and technologies to meet your specific needs. Simply tell us your requirements, and the industrial chiller can accommodate nearly all your applications.

Environmentally Friendly

Currently, regulations regarding chillers strictly emphasize environmental protection. With this in mind, industrial chillers use eco-friendly cooling media, refrigerants, and coolants. You can use them with confidence, without worrying about regulatory inspections, environmental pollution, or potential health risks to employees.

Industrial Chillers Installation Tip

Site: Choose a location with flooring or mounting pads that can support the weight of the chiller unit.

Temperature: Select an installation environment with sub-zero or room temperatures between 4.4°C and 43.3°C based on your specific needs. Different types of industrial chillers have different operating temperature requirements—incorrect temperature conditions may hinder operation or cause overheating.

Ventilation: Industrial chillers generate a significant amount of heat during operation. If this heat cannot be properly discharged, it may affect performance or even lead to safety issues. Therefore, installation in a well-ventilated area is essential, allowing ambient air to assist in heat dissipation.

Space: Regardless of the type of chiller or whether you are using it in large-scale or small to medium-sized applications, it’s important to leave enough space around and above the unit for installation, maintenance, and future upgrades.

Conclusion

In summary, industrial chillers play a vital role in maintaining equipment reliability and ensuring high production efficiency and quality—especially in the manufacturing, pharmaceutical, and chemical sectors. With options such as air-cooled or water-cooled systems, advanced inverter technology, and rapid cooling capabilities, you can freely configure the unit to meet your specific needs.

At LNEYA, our industrial chillers go beyond basic cooling performance. They are engineered to support your company’s long-term development by aligning with international standards and promoting sustainable, eco-friendly operations. Ultimately, we are committed to delivering economically reliable and high-value industrial chiller solutions tailored to your future growth.

Recommended chillers

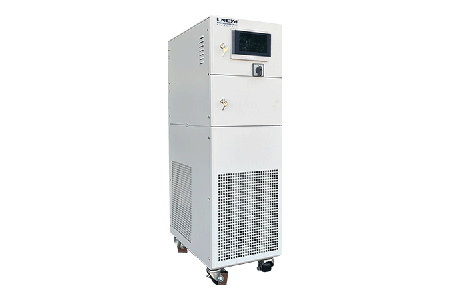

LTZ +5℃-90℃

glycol chillers

Cooling capacity 4kW~20kW

Heating power 3.5kW~15kW

temperature accuracy ±0.3℃

LTZ -40℃~90℃

fluid chillers

Cooling capacity 0.7kW~11.5kW

Heating power 2.5kW~10kW

temperature accuracy ±0.3℃

LTZ +5℃~30℃

laboratory chillers

Cooling capacity 23kW~155kW

Circulation Pump MAX 5m³/h~28m³/h 2bar

temperature accuracy ±0.5℃

LTZ -25℃~30℃

sub zero chillers

Cooling capacity 7kW~64.5kW

Circulation Pump MAX 2.5m³/h~15m³/h 2bar

temperature accuracy ±0.5℃

LTZ -45℃~20℃

coolant chillers

Cooling capacity 5.7kW~32.4kW

Circulation Pump MAX 1.5m³/h~7.7m³/h 2bar

temperature accuracy ±0.5℃

LTZ -60℃~-30℃

air cooled chillers

Cooling capacity 6.2kW~31.7kW

Circulation Pump MAX 2.4m³/h~12.1m³/h 2bar

temperature accuracy ±0.5℃

LTZ -80℃~-50℃

water cooled chillers

Cooling capacity 3.7kW~30kW

Circulation Pump MAX 2.3m³/h~12m³/h 2bar

temperature accuracy ±0.5℃

LTZ -115℃~-80℃

cryogenic chillers

cooling capacity 0.6kW~2.8kW

Circulation Pump MAX 20L/min~40L/min 2bar

temperature accuracy ±0.5℃

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier