Energy storage system requirements for temperature-controlled liquid-cooled unit

Energy storage system: It needs to meet the discharge demand for a long time. It is suitable for energy storage on the side of new energy generation, arbitrage of peak-valley price difference on the user side, etc. The future trend is that the project capacity will continue to expand. Under the trend of high installed capacity growth of new energy power generation projects such as wind energy and solar energy + expansion of distribution and storage ratios, energy storage projects on the power generation side are expected to accelerate their growth and production capacity will also expand. Therefore, for energy storage projects, the increase in battery system capacity will increase the calorific value of the project, and the demand and importance of thermostats will increase accordingly.

Secondly, in the design and development stage of the energy storage system, it is necessary to test the energy density. The ambient temperature needs to be controlled during the test to ensure the accuracy of the test results. Our liquid coolers provide them with a stable ambient temperature.

Energy storage systems are usually installed in a closed environment, and the environment needs to be controlled to ensure the stable operation of the energy storage system. Our devices can provide stable temperature control for energy storage systems while controlling indoor air quality. In the operation of the vehicle energy storage system, other auxiliary equipment will be used, and these equipment also need to be cooled and controlled by constant temperature.

The temperature control system can keep the temperature of the energy storage battery equipment within a reasonable range of 10-35°C, effectively preventing thermal runaway, and is a key link in the security of the energy storage system. The temperature is 15°C~35°C; the relative humidity is between 5%-95%, without condensation; this avoids local hot spots in the battery system: the temperature difference between the cells does not exceed 5°C to avoid local hot spots. With the trend of mass storage systems and high battery rates, temperature controllers are becoming more and more important. Additionally, temperature control increases lifetime decay by reducing temperature differences between cells.

The industry barriers of energy storage temperature control are mainly reflected in temperature control capabilities, product customization capabilities, and cost control capabilities. As an important part of energy storage systems, thermal management systems will benefit from the growth of installed energy storage capacity, and the energy storage temperature control market may continue to expand. We, LNEYA, are a manufacturer with 16 years of experience in manufacturing industrial temperature control equipment. We have pharmaceutical and chemical industries, new energy batteries, automobiles, semiconductors and other enterprise customer groups, so we are also very selective in the energy storage industry.

RECOMMENDED PRODUCTS

- Visit More

Cooling system of liquid-cooled energy storage cabinet-chiller

1109With the development of new energy technology, the application of containerized energy storage systems in new energy, photovoltaic, and electric energy stations has increased. If the temperature of the energy storage battery pack is not well…

- Visit More

Liquid Cooling Chiller(Commercial Energy Storage)

2322Battery Energy Storage Systems are filled with many battery cells, generating a large amount of extreme heat load. This means that the cooling system needs to precisely control the temperature and efficiently dissipate the l…

- Visit More

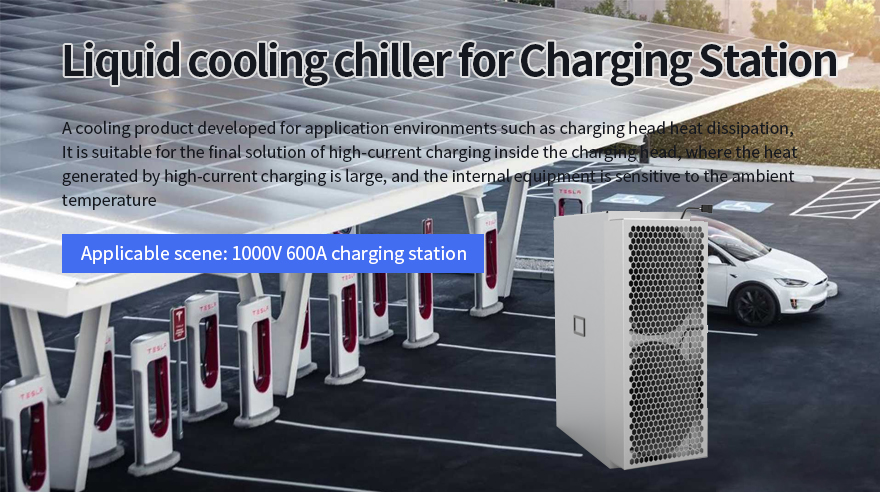

Liquid Cooling Chiller(Charging Pile)

2249Model CHDYL-4 -45℃~55℃ Cooling Power 4KW Temp control accuracy ±1℃ Real-time temperature record Refrigerant Brine circulation system fully enclosed design Flow 1.8~5.5L/min Pressure 0.7bar Minimum water inlet temperature 15°C …

- Visit More

Liquid Cooling Chiller(Energy Storage)

3178Model CNYL -45~55 Cooling Capacity 45KW Temperature Control Accuracy ±0.5℃ Real-time temperature record Secondary Refrigerant Ethylene glycol antifreeze, fully enclosed design of refrigerant circulation system Refrigerant R41…

loading…

已经是到最后一篇内容了!

Related recommendations

-

How to deal with the equipment failure alarm of the recirculating chiller

1246What to do if there is a failure and alarm during the use of the recirculating chiller equipment? In order to ensure production, such problems need to be resolved quickly. We must first understand the causes of failures and alarms, and adopt diff...

View details -

cryogenic chillers for drugs flow chemistry processes

786Low temperature chillers used in drug flow chemistry (continuous manufacturing) processes are one of the key equipment to ensure that reactions occur under precise temperature conditions. Flow Chemistry is a continuous manufacturing techno...

View details -

Professional introduction of dynamometer with motor cooling device

1213In the test of AC and DC motor and power tool, the test equipment such as dynamometer is often used. The dynamometer mainly tests the torque, speed and output power of the motor. The speed of the dynamometer usually Professional introduction of d...

View details -

High temperature test equipment related troubleshooting

1054The high temperature test equipment is mostly caused by water shortage in the water circulation. This way, the purified water is replenished to the water tank until the water level meter on the lower right side of the water tank reaches about 80% ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier