Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

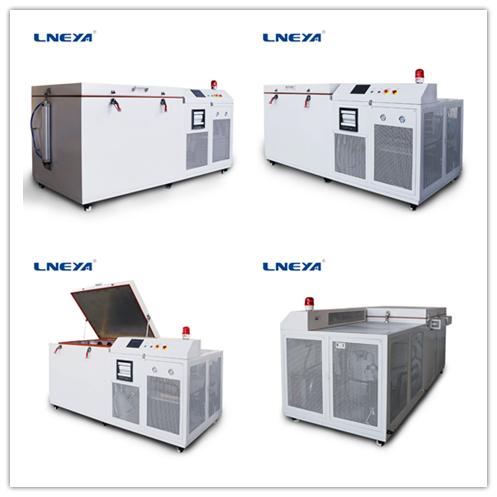

Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friendly refrigerant, which is conducive to the operation of ultra-low temperature refrigeration equipment. If the ultra-low temperature refrigeration equipment does not cool, how to Solve it?

Generally speaking, if the ultra-low temperature freezer is not cooled, there are four main reasons. One is that the filter is clogged. When the filter is clogged, the dust on the condenser will accumulate more and more, and the refrigeration effect of the refrigeration equipment will be affected over time. . In the long run, it may even cause refrigeration equipment to fail to cool. Solution to filter blockage: Clean the filter regularly or irregularly. It is also possible that the coolant content is small, and the ultra-low temperature refrigeration coolant content is too small, which may cause the equipment to not absorb oil and reduce the cooling effect. Less coolant content Solution: Always check the coolant to see if the coolant level is maintained at high or low, and add coolant when the coolant is too low.

If the refrigeration equipment is not cooled, there may be a lack of refrigerant. In the refrigeration, after the refrigerant is used for a long time, the refrigerant will volatilize after a long use time, thereby affecting the cooling effect. Solution: Refrigerant may have certain harm to the human body, so if you encounter this situation, you should find a professional refrigeration equipment company to add. There is also the possibility that the ultra-low temperature refrigeration supply voltage is low or the power of the refrigeration equipment is insufficient, and the equipment may not be cooled.

In general, the reasons and solutions for the non-refrigeration of ultra-low temperature refrigeration equipment are as shown above. It is recommended to find that the refrigeration faults are resolved in time to avoid affecting the production of the enterprise.

Related recommendations

-

Ic test equipment manufacturer test project description

1147Ic test equipment manufacturers need to pay attention to the test process when conducting project testing. Users can make the ic test equipment run more efficiently through detailed understanding. The ic test equipment is responsible for the exclu...

View details -

Matters Needing Attention in Replacing Refrigerant Oil of the Screw Chiller Factory

1108The refrigerant oil in the screw chiller factory needs regular inspection and replacement. We all know that different grades of refrigerant oil cannot be mixed together, otherwise it will cause abnormal or strike conditions of the screw chiller fa...

View details -

What should we pay attention to when storing the refrigerant of the chiller? What are the acceptance

1008Refrigerant is an essential substance to make the chiller have refrigeration effect, which has great potential safety hazards in the use process. Refrigerant, also called refrigerant, refrigerant carrier and snow seed, is used in different equipm...

View details -

The difference between direct contact liquid cooling and cold plate liquid cooling technology

1289The cold plate liquid cooling technology is an implementation method in which the heat of the heating components is indirectly transferred to the cooling liquid enclosed in the circulating pipeline through the cold plate, and the heat is...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier