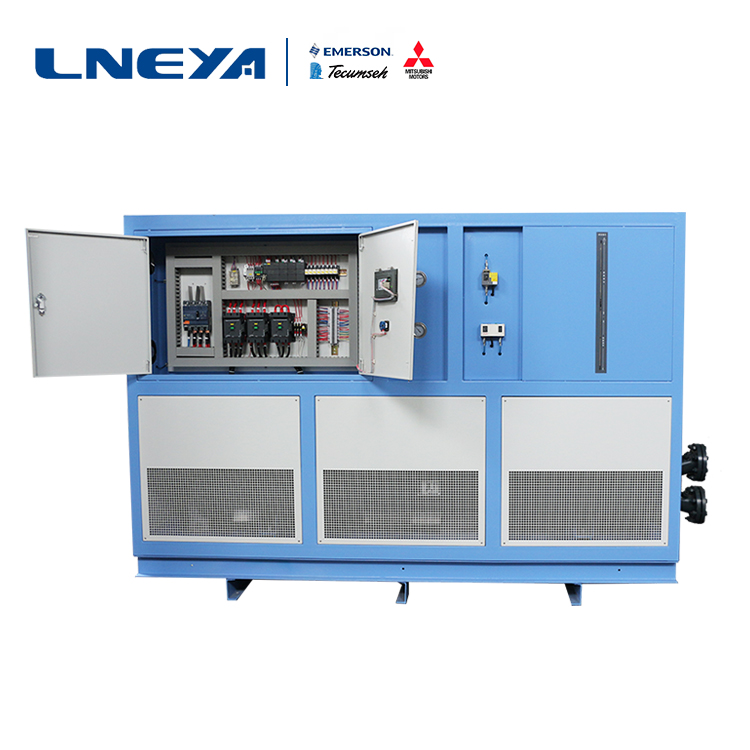

-220 °C refrigerator installation instructions

The appearance and weight of different models of -220 °C refrigerator are different, so the installation is also important.

-220 °C refrigerator should be placed indoors, should be placed in a solid and flat place, in order to reduce the vibration during the opening operation, you can put a layer of 12 ~ 20mm damping rubber between the -220 ° C refrigerator chassis and foundation Pads, installed and fixed according to the instructions, generally there will be professional and technical personnel to operate at this time, but also pay attention to the surrounding should have a certain space for operation, inspection, maintenance and use. The tools to be transported can be transported by forklift or by lifting with steel cables. However, we recommend using the latter because it avoids the strong impact during handling and the risk of damage.

The -220 °C refrigerator piping system shall be equipped with auxiliary equipment such as filters, water flow switches and water pressure gauges. The chilled water piping system shall be equipped with auxiliary equipment such as water flow switch, water pressure gauge, thermometer, differential pressure bypass valve and expansion water tank. Be sure to pay attention to the range of the power supply voltage. If the customer’s power supply system is not sufficient, on the one hand, it will not start normally, and then it may cause serious damage to the motor. When wiring installation, be sure to pay attention to the accuracy of the line. If the connection is not correct, it will not operate normally.

No matter where the -220 °C refrigerator is installed, it is recommended to read the instruction manual carefully before installation. If you encounter an installation problem that you do not understand, you can contact the relevant manufacturer’s technical personnel.

Related recommendations

-

Solution to the failure of the refrigeration and heating system of the reactor

1528When selecting the pipe material for the reactor refrigeration and heating system, you must pay attention to the connection of the pipe, the choice of the pipe and the material of the pipe. Because the pipe involves cooling and heating, you must r...

View details -

The ethylene glycol chiller solution is too cold and too hot

1643When the ethylene glycol chiller solutionis overheated and overcooled during operation, if you don't understand theseconditions well, you will not be able to operate the equipment well.The supercooling phenomenon of the solutionof the glycol ch...

View details -

LNEYA Is Exhibiting At Achema 2018

1183The LNEYA Group will participate in the ACHEMA -World Forum and Leading Show for the Process Industries,Frankfurt am Main, Germany.You will find us from 11st to 15th June 2018.Welcome to our booth(the detailed info is coming.),

View details -

What kind of refrigerant is selected by industrial chillers in different industries?

1366The refrigeration temperatures required by different industries for industrial chillers are different, so the choice of refrigerants is also different. Therefore, when choosing an industrial chiller, you need to have a clear understanding of the r...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier