What is the Most Energy Efficient Chiller

- Gas Chiller vs Electric Chiller What is the Difference

- What is the difference between indoor chiller and outdoor chiller

- What is the Most Energy Efficient Chiller

- What is the Difference Between Chillers and Coolers

- 4 Types of Refrigeration Systems Which One Fits Your Facility

- What is a VFD chiller VFD chiller vs Non VFD chiller

- What is a Gas Chiller

- What is a Scroll Chiller

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller chillers Cold Assembly Freezer cooling chiller cooling heating circulator cooling heating system cooling system dynamic temperature control system freezer heating circulator industrial chiller industrial cooling industrial freezer industrial refrigerator jacket reactor low temperature chiller news reactor chiller reactor cooling reactor cooling heating reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

As a chiller engineer who’s spent years on shop floors and in control rooms, you know a simple truth: the most energy efficient chiller is the one that fits your load profile, climate, and operations — not just the unit with the highest number on a data sheet.

Energy efficiency shows up in several design choices. Some matter more on paper. Others matter a lot more once the unit runs 24/7 and your utility bill arrives. Below we walk through the features our chiller experts pick first when they specify an energy efficient chiller for real plants.

High COP (Coefficient of Performance)

If you want one change that pays off fast, pick a VFD chiller. VFDs let compressors and pumps follow demand. Most users see them cut cycling losses and smooth out transient spikes. In a molding line or a lab that ramps up in the morning, VFDs keep the unit from hunting and wasting energy.

The control logic matters too, a sloppy VFD implementation can undo the benefits. So check how the drive integrates with the chiller controls.

Variable Frequency Drive (VFD) or Inverter Technology

If you want one change that pays off fast, pick a VFD chiller. VFDs let compressors and pumps follow demand. Most users see them cut cycling losses and smooth out transient spikes. In a molding line or a lab that ramps up in the morning, VFDs keep the unit from hunting and wasting energy.

The control logic matters too, a sloppy VFD implementation can undo the benefits. So check how the drive integrates with the chiller controls.

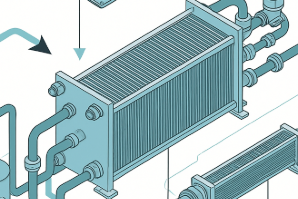

Advanced Heat Exchangers

Heat transfer is where physics wins or loses. Plate-and-frame and microchannel coils shrink the footprint and improve transfer efficiency. That means lower approach temperatures and less lift for the compressor.

For an air-cooled chiller in a hot climate, microchannel coils often yield better seasonal efficiency. For water-cooled plants, a compact plate heat exchanger reduces pumping energy and helps the whole loop run cooler.

Smart Controls and Monitoring

You don’t need a brainy dashboard for every site, but you do need controls that act on real signals. Smart controls tune setpoints, stage compressors, and shift operation toward efficiency automatically.

In the field, our engineers have seen units save energy simply by biasing setpoints at night when outdoor temps drop. Remote monitoring that only sends alarms is useless; look for analytics that suggest or apply optimizations.

Low-Temperature Lift Design

Temperature lift — the gap between chilled water and condenser temperatures — dictates compressor work. A low-temperature chiller design that minimizes lift reduces compressor stress and energy use. That’s where you get wins if you can also use free cooling or economizers. Design the system so the chiller doesn’t have to “fight” a hot condenser source every hour.

Efficient Fans and Pumps

Fans and pumps are often the overlooked energy sinks. Use variable-speed pumps and EC fans, and size them properly. In one plant that uses our industrial chiller, replacing a fixed-speed chilled-water pump with a VFD cut pumping energy by nearly half at typical loads.

Don’t oversize motors “just in case.” Proper pump curves and an unfussy control strategy save both energy and maintenance headaches.

Heat Recovery and Integrated Systems

Heat recovery changes the economics. A heat recovery chiller captures rejected heat and reuses it for domestic hot water or process heating. In hospitals or labs, that recovered energy can offset boiler loads. Even if payback looks long on the initial purchase, integrated systems often reduce total site energy and simplify operations. If your building needs both hot and cold, always evaluate a heat recovery option.

How to choose the right energy efficient chiller?

There’s no single “most energy efficient chiller” that fits every case. For variable loads, a VFD chiller with strong part-load COP and modern controls often wins. In climates with cool nights, a low-temperature chiller paired with free cooling can be unbeatable. If your site has simultaneous heating needs, a heat recovery chiller might deliver the best lifecycle value.

When we specify chillers, we stop at the datasheet and then ask two practical questions: how will this unit operate in my daily load curve, and how will it behave under part-load and transition events? Answer those honestly, and you’ll pick an energy efficient chiller that saves money and runs reliably for years.

Talk to LNEYA for an energy efficient chiller

If you are considering upgrading to a more energy efficient chiller, design matters as much as hardware. At LNEYA, we build chillers around real-world operating profiles, not just lab numbers. Our portfolio includes VFD chillers, high COP water-cooled units, low-temperature chillers, and heat recovery systems tailored for demanding industries.

Whether you run a precision lab, a molding plant, or a data center, our engineers can match you with a system that balances efficiency, stability, and reliability. Talk to LNEYA today and see how the right chiller can cut energy costs without compromising performance.

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier