How does the Industrial Water Chiller System Work?

When using industrial machinery, a cooling system may be required to prevent the machine from overheating. Refrigeration equipment can effectively keep materials in the optimal temperature range, but how does the chiller work? Understanding the working principle of industrial water chiller is very helpful to select the best refrigeration system to meet the needs of users.

Working principle of industrial water chiller

In short, industrial water chillers cool process fluids. Process fluid (usually water or water / glycol mixture) is used to cool machinery, equipment, etc. The process fluid absorbs heat from the cooled object and then passes through the chiller, where the heat is removed from the fluid and transferred to the ambient air.

Refrigeration circuit

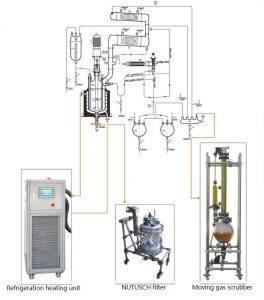

The industrial water or glycol chiller system consists of two main circuits: refrigeration circuit and fluid circuit. The refrigeration circuit consists of four parts: compressor, condenser, expansion valve and evaporator. The refrigeration circuit removes heat from the process fluid. The fluid circuit usually consists of fluid reservoir, pump, filter and heat exchanger. The fluid circuit carries process fluid around the cooled object.

Refrigeration cycle steps:

Refrigeration circuit is the most technical part of the working mode of chiller. The refrigeration cycle uses the principle of thermodynamics to effectively transfer heat from one region to another. In the case of a chiller, heat is extracted from the cooled fluid and transferred to the ambient air.

Compressor

The refrigeration cycle starts with the compressor. The compressor uses gaseous low-pressure and low-temperature refrigerant to compress it into high-pressure and high-temperature gas.

Condenser

The gas then flows through the coils in the condenser. In the condenser, air or water will flow through the coil and remove heat from the refrigerant. As the refrigerant loses heat, it will begin to condense until all the gases condense into a liquid.

Expansion valve

After leaving the condenser, the liquid passes through the expansion valve. The expansion valve limits the flow of refrigerant. When the high-pressure liquid passes through the expansion valve, it enters the evaporator.

Evaporator

The evaporator is where the refrigerant begins to evaporate. When the refrigerant evaporates, it becomes very cold and absorbs a lot of heat. The process fluid will interact with the cold refrigerant in the evaporator. Heat is removed from the fluid and transferred to the refrigerant. The refrigerant then enters the compressor and the cycle begins again.

Related recommendations

-

High-quality professional equipment helps the laboratory to produce endless results

2783In recent years, China's economy has continued to grow. Under the development opportunity of professional high and low temperature integrated machines, laboratory scientific and technological achievements are also in sustainable development. LNEYA...

View details -

What Are The Characteristics Of Refrigeration Of Industrial Chillers?

1716If there is a high temperature difference between the inlet and outlet water, then a large external tank will be used to store cold water. In this case, the cooling water will not be directly from the cooler application. Deep into the outside of t...

View details -

LED LCD display thermal test system operation process

1510The integrated semiconductor industry has developed rapidly in the past two years, which has driven other industries around it. The chip thermal test system is one of the products. In order to avoid machine failures in the LED liquid crystal displ...

View details -

Semiconductor diffusion furnace configuration temperature control equipment

1600In the semiconductor industry, a diffusion furnace is a device used to manufacture doping layers on the surface of semiconductor materials. It achieves the doping process through high-temperature heating and controlled diffusion atmosphere...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier