Automotive antifreeze test test temperature control system

When it comes to car antifreeze, we all know that its main function is to prevent the coolant from freezing and cracking the radiator and freezing the engine cylinder block or cover when we stop in the cold winter. Make the cooling system in the best working condition and ensure the normal working temperature of the engine.

The freezing point of water is 0°C, and ordinary antifreeze can reach -40°C, while high-quality antifreeze should be able to reach about -60°C, and the antifreeze has a high boiling point. The boiling point of water is 100 °C, and the boiling point of high-quality antifreeze coolant is usually 110 °C above zero, so it is more difficult to boil antifreeze coolant than water in summer.

Antifreeze detection items: freezing point detection, antifreeze detection, low temperature stability, thermal stability, etc. In these tests, temperature control is left off. When the testing organization carries out these testing items, it is necessary to ensure the constant temperature environment, cooling and heating temperature difference, time and so on during the testing process.

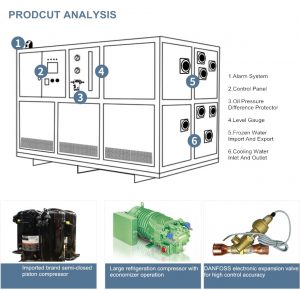

LNEYA automotive antifreeze cooling, heating, temperature control and flow system KRY series equipment is the temperature and flow control equipment required by this type of organization. The temperature range is minus 40 degrees to 100 degrees. The temperature changes during the test are visualized, and the data storage and report analysis can be exported for the convenience of the technicians of the testing organization.

The temperature test mentioned here is the high temperature endurance test and the low temperature endurance test. The low temperature endurance test mainly tests the cold start performance, the charging and discharging ability, the charging and discharging ability of the battery pack at high temperature, the cooling function of the battery pack and the overheat protection strategy.

Our LNEYA KRY series cooling, heating, temperature and flow control systems are the best choice for testing institutions, saving costs and increasing the efficiency and accuracy of testing.

Related recommendations

-

Ic test equipment manufacturer test project description

1082Ic test equipment manufacturers need to pay attention to the test process when conducting project testing. Users can make the ic test equipment run more efficiently through detailed understanding. The ic test equipment is responsible for the exclu...

View details -

LED LCD display thermal test system operation process

924The integrated semiconductor industry has developed rapidly in the past two years, which has driven other industries around it. The chip thermal test system is one of the products. In order to avoid machine failures in the LED liquid crystal displ...

View details -

The Importance of Electric Vehicle Battery Testing Chillers

985The Importance of Electric Vehicle Battery Testing Chillers

View details -

Industry and introduction of low temperature chiller

938In petroleum refining, petrochemical industry, organic synthesis, chemical products and other industrial production, refrigeration technology must be applied to control the reaction temperature during processes such as liquefaction, condensation, ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier