Relationship Between Condensation Temperature And Condensation Temperature In Ultra Low Temperature

The chilling temperature of the ultra low temperature recirculating chillers refers to the temperature at which the state of the substance changes from a gaseous state to a liquid state under a certain pressure. Different substances have different condensation temperatures. For the same substance, changes in external pressure can also cause changes in the condensing temperature. The condensation temperature of the pure substance is a temperature point, and for the mixture, the boiling range elongation condensation is a temperature range. In general, as the outside air pressure increases, the condensing temperature also rises, and vice versa. In short, it is a function of matter, composition and pressure.

The level of condensation temperature depends mainly on the temperature and flow rate of the cooling medium, the condensation area and the form of the condenser. Reducing the condensing temperature can increase the refrigeration capacity of the compressor and reduce the power consumption, thereby increasing the refrigeration coefficient and improving the economics of operation. However, the condensing temperature should not be too low, otherwise it will affect the circulation of the refrigerant, and the cooling capacity will decrease. If the condensing temperature is too high, not only the cooling capacity will decrease, but also the power consumption will increase, and the exhaust temperature of the compressor will increase, the temperature of the lubricating oil will increase, and the viscosity will decrease.

There is also a certain correspondence between the condensation temperature of the ultra low temperature recirculating chiller and the condensing pressure. Therefore, the adjustment of the condensing temperature can also be achieved by adjusting the condensing pressure. When the temperature of the cooling medium (water or air) is constant, the adjustment of the condensing pressure can be achieved by changing the flow rate and the condensation area of the cooling medium. The flow rate of the cooling medium is increased, and the flow rate is correspondingly increased, the heat transfer temperature difference can be reduced, thereby reducing the condensation temperature; and increasing the heat transfer area can also achieve the purpose of reducing the condensation pressure.

Related recommendations

-

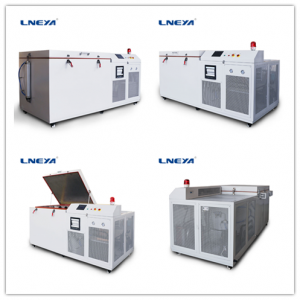

Notes on Purchasing Low Temperature Chamber

1474Welcome to buy our high quality low temperature chamber.,

View details -

Precautions for operation of ethylene glycol utra-low temperature chiller at minus 30 degrees

1643The minus 30 degree ethylene glycol utra-low temperature chiller is a device that is used more in the pharmaceutical and chemical industry. When using it, you need to pay attention to its operating specifications to operate it. If used improperly,...

View details -

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1657Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

View details -

Description of high and low temperature circulation tank refrigeration process

1993In the process of using high and low temperature circulating tanks, there may be some minor problems due to improper use, and there may be problems in the refrigeration process of Wuxi Guanya high and low temperature circulating tanks, and then we...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier