The role of temperature control system TCU in chemical and pharmaceutical reactor

The temperature control of the reaction kettle in drug research and development and chemical experiments, as well as the temperature control in small-scale experimental production and industrial production processes, require highly dynamic temperature control systems. When controlling the temperature of the reaction kettle, it is necessary to quickly and efficiently compensate for the absorption and exotherm of the chemical reaction.

Many reactors mix or chemically react materials, often accompanied by exothermic or endothermic processes. This part of heat needs to be balanced by a device to maintain a certain temperature range to ensure normal production. ,

Reactor temperature control requires different heating and cooling rates according to different reaction material characteristics. The working environment of some reactors has special requirements, which affects temperature control. How to accurately control the temperature of the reactor needs to be on site Understand the process conditions, such as explosion-proof treatment, or the control part is separated from the mechanical part.

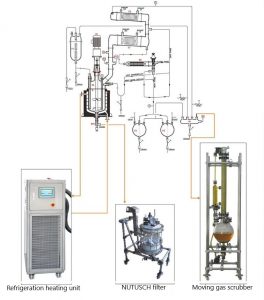

Most temperature control applications involve stainless steel and glass reactors. The stainless steel reaction kettle is more durable, while the glass reaction kettle allows users to observe the reaction process in the kettle body. The reaction kettle generally has an internal cavity, and the materials to be temperature controlled are placed in this cavity. The internal cavity is surrounded by a jacket through which heat transfer oil can pass. The temperature control system is connected to the jacket of the reactor. In order to control the temperature of the reaction kettle, the temperature control system continuously drives the heat transfer oil into the jacket of the reaction kettle through the circulation pump. The sudden temperature change inside the reactor will be compensated by the rapid heating and cooling of the temperature control equipment to achieve dynamic balance. The thermal oil is heated and cooled in the temperature control equipment.

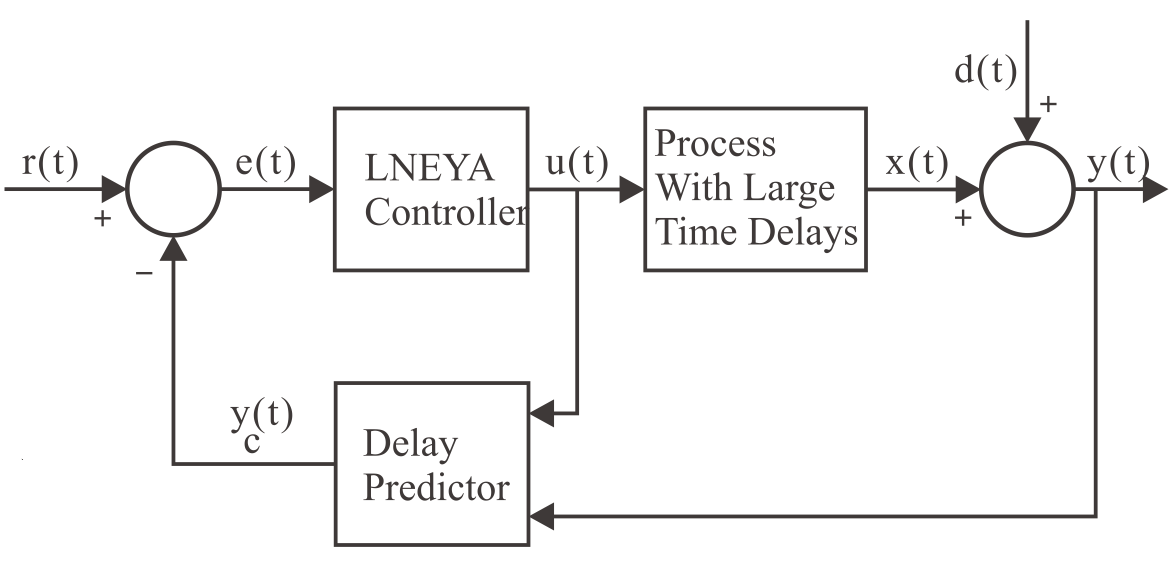

The LNEYA reaction kettle temperature controller TCU uses concentrated heat energy in the kettle to control the temperature of the process, ensuring that only one type of thermally conductive liquid flows into the jacket of the reaction vessel, reducing the problem of thermal reaction delay. Through three-point temperature sampling (material temperature point, temperature control system outlet and inlet temperature), there is no built-in expansion tank, which ensures that the heat absorption and heat release process will not affect the efficiency of the heat transfer oil. Due to the special type of the production workshop, we accept the customization of explosion-proof models, just need to tell us the temperature control effect you want to achieve.

Related recommendations

-

Application Note of Low Temperature Refrigerator for Cold Shrink Assembly of Automobile Engine Parts

1846Engine assembly is carried out in a low-temperature environment below minus 30°C in a low-temperature refrigerator. The mainstream automobile engine manufacturers have their own low-temperature assembly workshops. Engines assembled in a low-temper...

View details -

-

Analysis of the environmental requirements of the -20 °C freezer

1632Due to the difference in ambient temperature, there are certain requirements for the freezer. Today LNEYA came to tell you how the ambient temperature is good for the -20 °C freezer. Now there are many types of freezer boxes: hot and cold temperat...

View details -

Purchasing Strategy of Ultra-low Temperature Freezer

1356The performance of refrigeration system determines the overall performance. If refrigeration technology is good, excellent refrigeration effect can be achieved quickly. It takes only 4-5 hours on average from room temperature to minus 8 degrees Ce...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier