Maintenance of Glycol Cooling Heating Control System

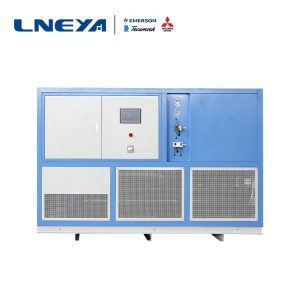

Apart from the attention needed during the daily use, the regular check and maintenance of Glycol Cooling Heating Control System are also very important. In order to help all of you learn to use Glycol cooling heating more efficiently, LNEYA Refrigeration sort out related maintenance, so that you can use it in time.

Screw Compressor

Screw compressor is a very important part of ethylene glycol refrigerator, and the compressor is directly related to the stability of the unit. If the compressor has something wrong, In view of the high precision of the assembly precision of the screw compressor, the factory is usually required to carry out the maintenance, so it needs to be paid more attention in the ordinary use process in using.

Condensers and Evaporators

Is there is something wrong with the Glycol cooling heating control system, in view of the high precision of the assembly precision of the screw compressor, the factory is usually required to carry out the maintenance, so the compressor needs to be paid more attention in the ordinary use process.

Washing of condensers and evaporators

The cooling water of the water-cooled condenser of glycol refrigeration unit is open loop circuit. The circulating water is usually used by the cooling tower. When calcium the content of salt and magnesium salt in water is large, it is easy to decompose the fouling between the pipe and rock, and the heat transfers. Once the scale of the condenser of glycol cooling system is too thick, the cross section of the cooling water will decrease, the water volume will decrease and the condensing pressure will increase. Therefore, when the water quality of the cooling water is poor, the cooling water pipe should be washed at least once a year to remove scale and other contaminants. Of course, not only glycol cooling system but other other related cooling equipment used for a period of time, their maintenance knowledge is needed to learn in everyday use.

Related recommendations

-

-80 °C refrigerator manufacturer operating equipment points

1485When the user chooses the -80 °C refrigerator, it is definitely necessary to have a reliable quality. Wuxi Guanya (LNEYA)-80 °C refrigerator should pay attention to its operation details during operation to avoid equipment failure caused by improp...

View details -

Operation LNEYA high and low temperature cycle machine note

1668LNEYA high and low temperature cycle machine uses mechanical refrigeration to obtain low temperature heating tube heating to obtain high temperature. It is used with various glass reactors and reactors. What should be paid attention to when using ...

View details -

-

Three integrated thermal shock test chamber cooling method

1804The three integrated thermal shock test chambers are designed and manufactured according to user requirements. They are suitable for high and low temperature impact tests of high-temperature or low-temperature environments and for high-temperature...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier