Characteristics and applications of glycol chillers

Glycol chiller is applied to the cooling process of grinding machines, CNC machine tools and various precision machine tools, which can effectively reduce the thermal deformation of machine tools, improve the machining accuracy of machine tools and accurately control the oil temperature.

Simply put, the output cold water temperature can be adjusted between 3-35 ℃. The water chiller is used to cool the forming molds of plastics, rubber and processing machinery, so that the products do not deform and shrink, accelerate the finalization of products, facilitate the demoulding of plastic products, reduce the surface marks and internal stress of plastic products, greatly improve the surface finish of plastic products, and greatly improve the production efficiency of plastic forming machine.

Glycol chiller has the following important features:

1. The glycol water chiller has perfect safety protection devices and abnormal indication system such as electronic time delay, current overload protection and high and low voltage protection. Use the LCD to view the cold water inlet, cold water outlet and set temperature.

2. Microcomputer is easy to operate (optional) and fully functional control.

3. The industrial chiller has a combination of two machines or single machine, with high refrigeration efficiency. Accurately control the water temperature at ± 0.5 ℃.

4. Industrial modeling design, more convenient man-machine operation, beautiful appearance and small floor area.

5. New high-efficiency shell and tube condenser and imported compressor, super refrigeration, saving power consumption.

6. Equipped with precision electronic temperature controller, it can accurately control the water temperature between 0 ℃ and 10 ℃.

7. The screen simultaneously displays the cold water inlet, cold water outlet and set temperature (optional).

8. The use of water chillers can increase the output by 20% and obtain greater benefits in the long-term production process. When selecting temperature control equipment, enterprises of production type should fully consider the specific heat capacity of molding materials, temperature and weight during glue melting, and select the most appropriate product model. The chiller has the advantages of small volume, low noise, long service life and simple operation. It has an atmospheric appearance, rigorous and creative design, and has reliable and stable high-quality performance.

Related recommendations

-

Description of working principle of high and low temperature impact test chamber

1706Spot high and low temperature impact test chamber, also known as three-box high and low temperature impact test chamber, high and low temperature impact test chamber is mainly composed of low temperature storage chamber, high temperature storage c...

View details -

2023 LNEYA Spring Festival holiday notice

2323I have been busy all year, and I am happy to celebrate the new year. The Chinese New Year is coming, and LNEYA is also preparing for the Chinese New Year holiday! Combined with the specific situation of the company, the specific arrangements for ...

View details -

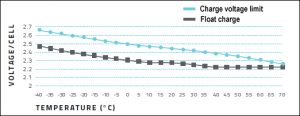

Is it right to extend battery life by lowering the ambient temperature?

1477The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

View details -

Maintenance knowledge of 12HP (8.9kW) low temperature chiller

1783The user can arrange the operator to learn about the daily maintenance knowledge of the 12HP (8.9kW) low temperature chiller after purchase. It can not only improve the company's product quality, improve production efficiency, but also extend the ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier