Guide to Glycol Recycling in Chiller Systems

Industrial glycol may oxidize or degrade after long-term use. In order not to affect the cooling effect of the chiller system, it needs to be replaced regularly. However, direct discharge will pollute water sources and soil, and glycol is expensive. It can be used again after treatment, so glycol recovery is required. This article introduces common methods for recovering glycol.

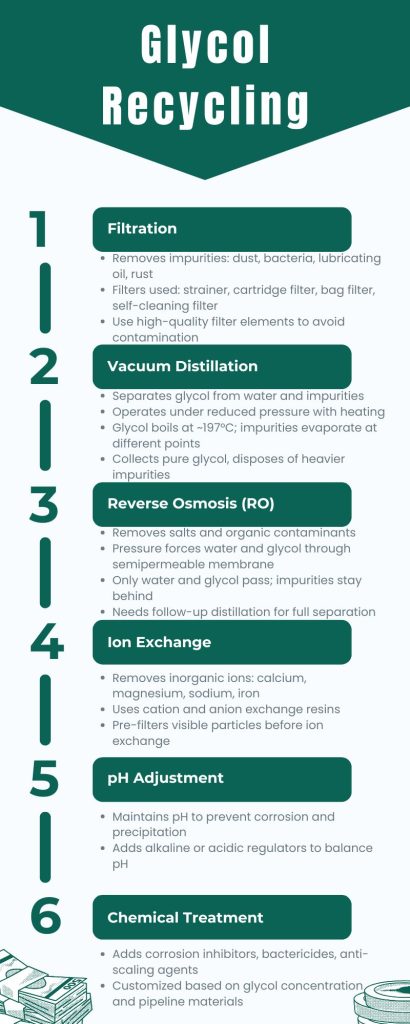

Filtration

Glycol systems will be mixed with impurities after long-term use. These impurities may be dust, bacteria, lubricating oil or rust particles. Although they are small, they will reduce the thermal conductivity of glycol and even damage components. Therefore, these impurities need to be filtered out during recycling. Professionals will use strainer, cartridge filter, bag filter and self-cleaning filter to filter impurities of different sizes according to the flow rate of the system. It should be noted that you must choose a regular brand of filter element, otherwise it may contaminate glycol.

Vacuum distillation

Vacuum distillation can separate glycol from water and impurities, and improve the purity of glycol for secondary use. During operation, our technicians will first use a vacuum pump to reduce the pressure in the distillation tower and heat the glycol mixture to be recovered. Since the boiling point of glycol is around 197°C, impurities with lower boiling points will evaporate first, and glycol will then evaporate and condense into liquid to be collected. The remaining impurities with higher boiling points than glycol will be processed centrally.

RO (Reverse Osmosis)

RO technology is commonly applied in glycol recovery to separate slightly soluble salts and organic contaminants from glycol. After applying pressure, water can flow from high concentration to low concentration through a semipermeable membrane. Because the pore size of the semipermeable membrane is very small and glycol and water are highly compatible, only water and glycol can pass through during the separation process, while impurities are left on the other side. Water and glycol cannot be completely separated by RO technology, and subsequent distillation is required.

Ion exchange

Ion exchange can remove inorganic ions such as calcium, magnesium, sodium, and iron in glycol mixtures to improve the purity of glycol. Professional treatment will first use a coarse filter to remove visible particles in the solution, and then use cation and anion exchange resins to absorb ions in the solution respectively.

pH adjustment

Glycol solution with high acidity will corrode metals, and high alkalinity will form precipitation and block pipelines. Therefore, the pH needs to be maintained within the appropriate range. Adding alkaline and acid regulators to the solution can change its pH value.

Chemical treatment

In order to prevent glycol solution from corroding pipelines or breeding microorganisms and forming scale, we usually add corrosion inhibitors, bactericides and anti-scaling agents to it. The type and amount of agents will depend on the glycol concentration and pipeline material.

Conclusion

We hope that after reading this article, you have a deeper understanding of the common methods of recovering glycol. If you need technical support or a reliable glycol chiller, LNEYA team is happy to help you. Ask us!

Related chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier