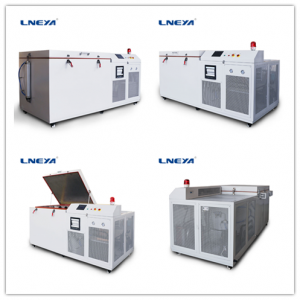

Ethylene glycol refrigeration unit made a strong attack and created LNEYA brand in 12 years

Performance enhanced positioning

When performing the cooling and heating reaction, in many cases, the refrigerant cannot cool the object to be cooled by itself. Therefore, we need a coolant (or refrigerant) to cool the refrigeration system in a relatively small range. The suitable brine is undoubtedly ethylene glycol. Compared with water, the freezing point is high and the salt water is corrosive. Ethylene glycol is currently a suitable refrigerant for everyone.

Therefore, in response to this situation, LNEYA refrigeration has introduced a glycol refrigeration heating control system to deliver cooling to the process side. Although the cost of ethylene glycol is slightly more expensive than water, Guanya Refrigeration uses a fully enclosed circulation system to avoid waste and can be recycled many times, which is quite energy efficient. In the specific operation, the tested object is connected to a test platform adapter. The inside of the component is cooled and heated by the aqueous solution of ethylene glycol. The component is placed in the environmental chamber as a whole. The environmental chamber provides a high and low temperature environment. Good and efficient operation, and thus widely used in industry.

Good quality has good products, product quality is the core

In the reaction of the ethylene glycol refrigeration heating temperature control system, it is necessary to have a specific temperature change process. In order to give everyone a clear display process, the display screen can be specially set to record the temperature change, and Can be intuitively felt. In general, the temperature is set from -40 to -150 ° C, and the cycle is usually performed when the tolerance test is carried.

International brand configuration

LNEYA refrigeration brings you the ethylene glycol refrigeration heating temperature control system is not an ordinary configuration, but through continuous testing and continuous trial and error to achieve large refrigeration heating effect of international brand accessories, such as pump configuration is strong temperature resistance The pressure-resistant gear pump provides high flow at a constant pressure output, quickly achieves the required pressure, and provides constant control over preset pressure values while ensuring high viscosity liquid delivery. The pump adopts variable frequency speed regulation to ensure the heat exchange of excellent load (the flow rate of water glycol mixture is about 50 liters / minute), and the integrated Siemens frequency converter ensures high speed and speed control to meet the application requirements.

Fully enclosed refrigeration system

The ethylene glycol refrigeration heating temperature control system adopts a fully closed circulation system, which avoids the opportunity of contact between the heat conductive liquid and the outside air to ensure the condensation of water. The expansion tank is protected by nitrogen, and the temperature range of the heat transfer liquid is also broadened because its boiling point is increased. In addition, oxidation of the thermally conductive liquid in contact with oxygen in the environment is also avoided, thus extending the useful life of the thermally conductive liquid.

Accurate temperature control, high automation

LNEYA refrigeration glycol cooling heating temperature control system pays special attention to repeatability and high precision in the test results. For this reason, the S7-200 Siemens PLC control is set on the refrigeration system, which provides clear and comprehensive data feedback, and the electrical control part is basically All controls can be done without human intervention. Because of this high level of automation, the labor required to withstand testing is small, industrial process thermostats can work reliably from 5 to 40 degrees Celsius, and in the hot summer months, high temperature to 30 degrees of cooling water can be used. jobs. The IP54’s safety protection design meets the high safety requirements of the equipment, which means that the equipment can be used in very demanding production environments.

LNEYA refrigeration glycol heating and temperature control system is widely used in the industry. In addition to the 12 years of professional production, the quality of the products is also obvious to everyone. It can ensure high safety and production needs. In the future, a hurricane can be blown up. In the next 12 years, we look forward to better LNEYA refrigeration and look forward to better refrigeration and cryogenic equipment.

Related recommendations

-

Methods for Chiller Manufacturers to Ensure Product Quality

1040Before producing the industrial chiller, the chiller manufacturer will consider the applicable industry, refrigeration capacity, structure, etc., and consider the actual use environment during design and assembly to optimize some functions. In ord...

View details -

What to consider when purchasing an oil-cooled motor power cooling system?

1032Purchasing objects is nothing more than based on several types of methods: inquire with people around you, search and consult on the Internet by yourself, so that you can avoid some detours. 1. Parameter requirements: Ordering from the Internet is...

View details -

Analysis of the reasons for non-refrigeration of cryogenic refrigeration equipment

1134Ultra-low temperature refrigeration equipment is mainly used in industrial cold processing. Unlike some manufacturers of ultra-low temperature refrigeration equipment, LNEYA ultra-low temperature refrigeration equipment uses environmentally friend...

View details -

Heavy Industry Workpiece Cold Assembly Freezer

858In the heavy industry, cold assembly freezers (also called industrial freezers or cryogenic freezers) are used to cool and store large workpieces or materials to meet specific process requirements. This equipment is often used in metal...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier