-80 °C refrigerator manufacturer operating equipment points

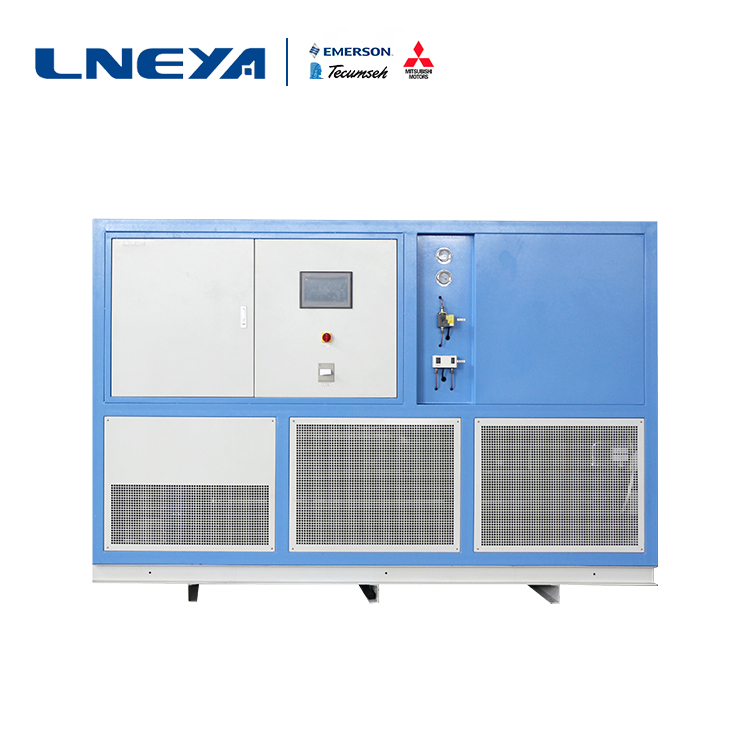

When the user chooses the -80 °C refrigerator, it is definitely necessary to have a reliable quality. Wuxi Guanya (LNEYA)-80 °C refrigerator should pay attention to its operation details during operation to avoid equipment failure caused by improper operation.

The following items should be mastered during use. Please check if the -80 °C refrigerator is damaged during installation, and choose the right place for installation and future maintenance. The site where the unit is installed must be the floor, mounting mat or foundation with a level of 6.4 mm and can withstand the operating weight of the unit. – It should be placed in a machine room with a room temperature of 4.4-43.3 °C. There should be enough space around and above the unit for routine maintenance work. A pipe space for cleaning the condenser tube bundle should be left at one end of the device, or a door hole or other suitable hole can be used.

Select the water pipe of the appropriate pipe diameter, the cooling system and the cold water system of the -80 °C refrigerator unit during high power operation, and connect them correctly. For normal applications, the water flow rate through the evaporator and condenser is between 1.0 and 3.6 m/s.

Under any load, the water flow rate should be stable. All chilled water and cooling water pipes should be designed and installed according to the conventional method. The chilled water pump should be located on the inlet pipe of the unit to ensure the positive pressure and flow in the unit. The piping should be provided with a damping tube to ensure proper flexibility and to prevent the evaporator water from being drained when the pump is shut down. The piping should have a solid support independent of the -80 °C refrigeration unit to prevent stress from being applied to the refrigeration unit components. The hangers are set up to facilitate pipe alignment.

-80 °C refrigerator manufacturers will provide corresponding instructions when the equipment is shipped from the factory, users need to read and operate carefully when using.

Related recommendations

-

60P ultra-low temperature water chiller consumes too much energy and needs attention

90360p ultra-low temperature water chillers of different manufacturers have different performance configurations and different energy consumption. If you find that the energy consumption is too large, you must check in time to see if there is a probl...

View details -

Working characteristics of industrial high temperature and low temperature cooling system

991The industrial high-temperature and low-temperature cooling system is mainly used for the monitoring and control of temperature, pressure, flow, liquid level, humidity, pH value and other parameters. It has the characteristics of high control acc...

View details -

Rapid temperature change test chamber temperature control instructions

1100The selection of the humidity range of the rapid temperature change test chamber should be noted that the corresponding temperature range should be indicated after the humidity index or the dew point temperature should be given. Because relative h...

View details -

The advantages of water cooled chiller you need to know

1107Industrial chillers can be generally divided into water-cooled and air-cooled according to the type of refrigeration. The heat exchange medium of Water Cooled Chillers is water.LNEYA has designed and developed a new type of temperature control equ...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier