How to repair the compressor failure in the industrial glycol temperature cycle machine

The industrial glycol temperature machine performs refrigeration and heating reactions under the required process conditions, and the compressor is used as its core accessory. If a fault occurs, the operator should pay attention to summarizing and analyzing the problem.

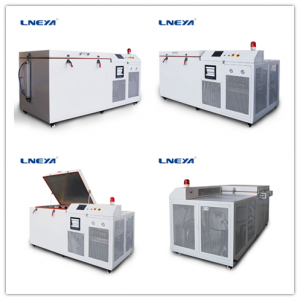

1. The industrial glycol temperature machine is divided into two parts: heating part and cooling part, which are widely used in chemical industry, reaction kettle and other industries. It can realize mutual switching, speed up the production progress, reduce energy consumption, improve the molding efficiency of products, and reduce the generation of defective products.

2. It is controlled by computer touch, automatic calculation, and multi-point temperature control unit can be customized. It can automatically control the temperature, and can quickly reach the set temperature. The set value and the actual value are displayed separately. Isolated electrical control box, prolong the service life of electrical appliances, pipeline explosion-proof device, built-in protection, low noise, high temperature corrosion resistance and rust resistance, unique heating design, power saving and durable, suitable for use in different temperature control places.

3. If the compressor is subjected to excessive load for a long time, the temperature will rise too high, which will damage the insulation and shorten the service life of the deceleration compressor.

4. All parts of the deceleration compressor should be kept clean, and the assembly of end caps, bearings, etc. should be reasonable, and the construction should not be brutal, otherwise the corresponding parts will be deformed by force, and the deceleration compressor will not be able to run.

5. Damage to the compressor bearing is a common fault in the operation of the deceleration compressor. The bearing is replaced again, and the interference of the compressor end cover is too large or the ovality exceeds the standard, which causes the bearing ball clearance to be too small or uneven, which leads to an increase in friction when the bearing is running, and the temperature rises sharply until it burns out.

6. The bearing cavity is not cleaned or the grease added is not clean. For example, the tiny rigid substances in the bearing cage are not cleaned up, and the bearing raceway is damaged during operation, causing the temperature to rise too high and burning the bearing.

7. The operating temperature of the compressor body is too high, and the bearing is not replenished with grease in time, causing the bearing to lack oil or even burn.

8. The bearing itself has manufacturing quality problems, such as raceway rust, inflexible rotation, excessive clearance, and cage deformation.

The working principle of the industrial glycol temperature machine is to use the pump to drive the heat transfer medium (usually water or oil) from the fuel tank equipped with the heater to the temperature control equipment, and then return from the temperature control equipment to the fuel tank. The controller adjusts the temperature of the thermal fluid according to the temperature of the thermal fluid measured by the temperature sensor or the internal temperature of the temperature control device, thereby adjusting the temperature of the temperature control device.

Related recommendations

-

Why does a chiller need to be installed for cooling the water storage tank?

994The main reasons for configuring a chiller for cooling the water storage tank are related to the following aspects: Temperature Control: In many industrial and commercial applications, such as air conditioning systems, chemical processes, ...

View details -

How to solve the phenomenon of ultra-low temperature freezer card cylinder?

1438If the ultra-low temperature freezer room fails during operation, it needs to be solved in time. If it is similar to the related phenomenon, it may be that the frozen oil does not come up, and the operator needs to solve it in time. Ultra-low temp...

View details -

Dual-channel chillers for semiconductor manufacturing industry

962Dual-channel chillers are used in a variety of processes in the semiconductor manufacturing industry. The main purpose is to provide precise temperature control to ensure that the equipment in the semiconductor manufacturing process operat...

View details -

What should I pay attention to when replacing a water-cooled chiller compressor

1011Once the compressor of the water-cooledchiller fails, the compressor needs to be replaced in time, but the replacementof the compressor is not as simple as imagined.Before the water-cooled chiller compressoris replaced, the reasons for the dama...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier