What Are Water-Cooled Condensers

Water-cooled condensers are a key component in many industrial cooling systems, especially in large-scale water-cooled chillers. Cooling systems use water as a cooling medium to remove heat from the refrigerant, condensing the vapor back into liquid. The water absorbs the heat and is then discharged, allowing the cycle to repeat.

These condensers are often preferred in situations where air-cooled systems wouldn’t be as efficient, particularly in environments where space is limited or where higher efficiency is needed.

How Do Water-Cooled Condensers Work?

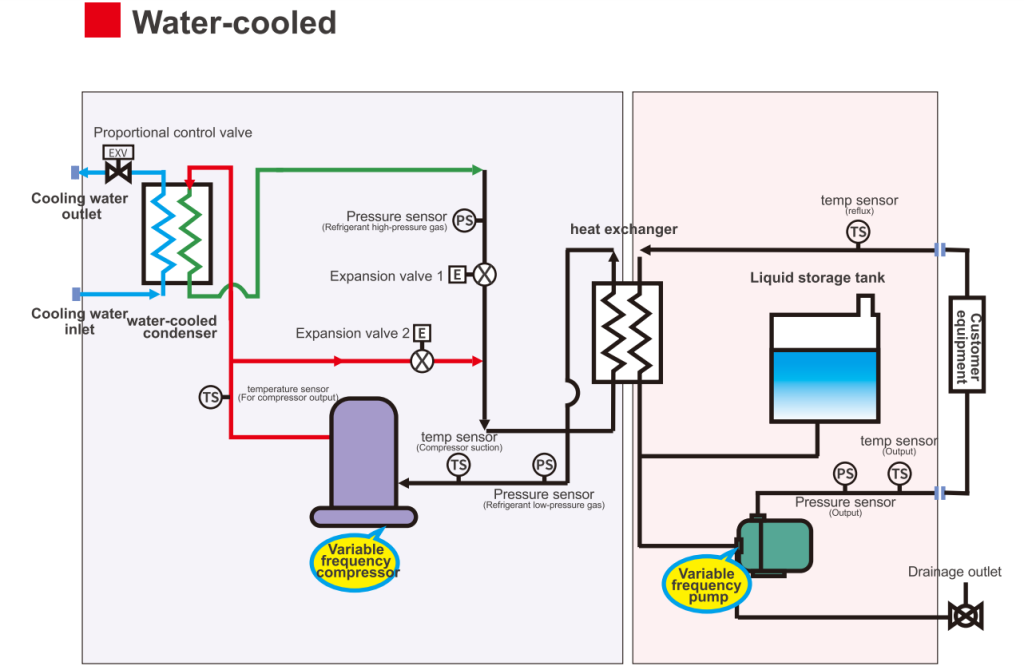

Water-cooled condensers operate based on a simple yet effective heat exchange process. The refrigerant, which is in gaseous form after being compressed by the compressor, enters the condenser coils. Here, it meets the cooling water, which flows through the condenser’s cooling tubes or shell.

As the hot refrigerant passes through the condenser, it transfers its heat to the water. The water absorbs this heat and cools the refrigerant, causing it to condense back into a liquid state. The heated water is then pumped away and replaced by cooler water to repeat the process.

Types of Water-Cooled Condensers for Industrial Use

In industrial settings, several types of water-cooled condensers are commonly used. Each type is suited to different applications, depending on factors like size, cooling load, and space availability.

Shell and Tube Condensers

This is one of the most commonly used types in larger industrial systems. In this design, water flows through the tubes while the refrigerant flows over the tubes, allowing heat exchange to take place effectively.

Plate Heat Exchanger Condensers

In these systems, refrigerant flows through plates with cooling water passing in parallel channels. The plates create a highly efficient heat exchange surface, making this type ideal for situations where space is limited.

Air-Over-Water Condensers

This type combines both air and water cooling. A fan blows air across the water-cooled condenser coils, helping to enhance the cooling process. These are commonly used when there is a need for a combined approach in heat dissipation.

What Are the Advantages of a Water-Cooled Condenser?

Water-cooled condensers offer several advantages that make them particularly appealing in certain applications.

Higher Efficiency

Water is a more effective heat transfer medium compared to air. This makes water-cooled condensers more efficient, especially in high-load or continuous cooling applications.

Compact Design

These systems are often more compact than air-cooled alternatives, making them ideal for facilities where space is at a premium.

Consistent Cooling Performance

Water temperature is less susceptible to fluctuations than air temperature, which means water-cooled condensers can provide more stable and reliable cooling over time.

Lower Operating Costs

While the initial setup for a water-cooled system can be higher, the long-term operating costs are often lower. The enhanced efficiency means less energy is required to cool the refrigerant, which can significantly reduce energy bills.

When Does a Chiller Use a Water-Cooled Condenser?

Chillers with water-cooled condensers are used in environments that require efficient and consistent cooling, particularly when air-cooled systems would not perform as effectively. For example, large-scale industrial operations such as data centers, chemical processing plants, and manufacturing facilities often use water-cooled condensers to maintain a consistent temperature.

Water-cooled condensers are also ideal for systems that need to operate in high-heat environments or need to cool larger amounts of refrigerant efficiently.

What Is the Difference Between Air-Cooled Condensers and Water-Cooled Condensers?

While both types of condensers serve the same basic purpose — cooling the refrigerant and turning it from gas back into liquid — they operate differently and have distinct advantages.

Cooling Medium

Air-cooled condensers use air to remove heat, while water-cooled condensers use water. Water, being more effective at heat transfer, allows for higher efficiency and more reliable cooling.

Space Requirements

Air-cooled condensers tend to take up more space because they rely on larger surface areas for heat exchange. Water-cooled condensers, on the other hand, are more compact and can fit into smaller spaces.

Energy Consumption

Water-cooled systems generally consume less energy than air-cooled systems because water transfers heat more efficiently. This means water-cooled systems can often provide the same level of cooling with lower energy usage.

Maintenance Needs

Air-cooled condensers are typically easier to maintain, as they don’t require a water supply system. Water-cooled condensers, however, need regular maintenance to ensure that the water system is clean, the water treatment is adequate, and there are no blockages in the pipes.

Talk to LNEYA Cooling Experts

Choosing the right cooling technology is a big decision. Whether a robust water-cooled condenser is the perfect heart for your chiller system, or another solution makes more sense, you don’t have to figure it out alone.

With years of experience across countless industries, our experts at LNEYA can cut through the complexity. We’ll help you understand the real-world pros and cons for your specific application, environment, and goals.

Stop guessing. Get a clear answer tailored to your plant’s needs. Reach out to our team today for a consultation.

- Chiller Components and Refrigeration Fundamentals Guides

- Chiller Types and Selection Guides

- How Does a Peltier Cooler Work

- Peltier Chiller vs. Compressor Chiller

- What Is a Peltier Chiller

- OEM vs Aftermarket Chiller Spare Parts

- Chiller Surge

- Chiller Cooling Capacity Units

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- September 2023

- July 2023

- June 2023

- May 2023

- January 2023

air cooled chiller chiller Chiller Installation Chiller Maintenance chiller refrigerant chillers Cold Assembly Freezer cooling chiller cooling heating system cooling system dynamic temperature control system energy efficient chiller explosion-proof chiller freezer heating circulator industrial chiller industrial chillers industrial cooling industrial freezer industrial refrigerator jacket reactor laboratory chiller low temperature chiller news oil chiller process chiller process cooling reactor chiller reactor cooling reactor cooling heating reactor heating cooling refrigerated circulator screw chiller semiconductor chiller semiconductor test chiller sundi tcu temperature control test chamber thermostat ultra low temperature chiller vehicle test chiller water chiller water cooled chiller

Related Chillers

CONTACT US

TEL:

EMAIL:

WeChat & WhatsApp:

Wechat QR

Have a question or need a quote? Fill out the form below, and our team will get back to you within 24 hours.

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier