GD Series Low Temperature Refrigerator

APPLICATIONS

Applied in industrial cold treatment low temperature testing, so that the uniform, fine and dispersed carbide precipitation produced on the metal structure matrix organization. The precipitation of carbides will significantly improve the wear resistance and friction performance of metals, increase hardness, and directly increase the life of wear parts. It is a liquid nitrogen substitute. It is used for cold shrinkage of copper sleeves, bearings, etc. and is widely used in precision machinery assembly.

Product Features

Product Parameters

| Model | GD-1100-B2-GYZ GD-1100-B2-GYZW |

GD-1100-C1-GYZ GD-1100-C1-GYZW |

GD-1100-C2-GYZ GD-1100-C2-GYZW |

GD-1100-D1-GYZ GD-1100-D1-GYZW |

GD-1100-E1-GYZ GD-1100-E1-GYZW |

| Effective volume | 1100L | 1100L | 1100L | 1100L | 1100L |

| Inner container size cm | 90*100*125 | 90*100*125 | 90*100*125 | 90*100*125 | 90*100*125 |

| Temperature range | -65℃~-35℃ | -80℃~-50℃ | -100℃~-70℃ | -120℃~-90℃ | -150℃~-110℃ |

| Control accuracy | Within the controllable temperature range of ± 0.5 ℃ | ||||

| Bearing capacity | 350kg Other load-bearing qualities can be customized | ||||

| Cooling capacity | No load, cool down to 25 degrees Celsius at room temperature (minimum temperature setting+10 ℃) for about 1 hour | ||||

| Temp uniformity | Within ± 2 ℃ | ||||

| Open mode | Side opening door, double layered interior and exterior door design, opening the exterior door automatically closes the circulating fan |

||||

| Evaporator | Electrophoretic copper tube with aluminum fins | ||||

| Compressor | Emerson Valley Wheel Vortex Compressor, Carlisle Semi Enclosed Piston Compressor | ||||

| Controller | Programmable PLC controller, 7-inch touch screen | ||||

| Safety protection | Having self diagnostic function; Refrigerator overload protection; Multiple safety protection functions such as high and low pressure sensors, overload relays, and thermal protection devices; Pressure balanced design ensures smooth door opening |

||||

| Data record | Temperature curve recording, USB data export in Excel format, fault record | ||||

| Defrosting function | Can set timed defrosting function | ||||

| Insulation layer | 150mm | 150mm | 150mm | 200mm | 200mm |

| Polyurethane foam secondary foaming+FIR board | |||||

| Refrigerant | R404A R23 | R404A R23 | Mixed refrigerant 1 | Mixed refrigerant 2 | Mixed refrigerant 3 |

| Material quality | Inner liner SUS304 shell cold-rolled plate spray coated with RAL7035 | ||||

| Refrigeration components |

Famous brands are used for condenser, plate heat exchanger, oil separator, pressure sensor, temperature sensor, drying filter, electronic expansion valve, gas-liquid separator, sight glass, frequency converter, etc |

||||

| Dimension | 120*235*170 | 120*235*170 | 120*235*170 | 130*250*180 | 130*250*180 |

| Power supply | 400V 50HZ | ||||

| Other sizes and load-bearing capacity can be customized | |||||

Product Advantages

- Efficient production stability and repeatability results;

- Using plate heat exchangers and pipeline heaters to improve cooling and heating rates;

- Very wide temperature range, no need to replace liquid medium;

- Fully enclosed system, extending the lifespan of thermal conductive liquids;

- Adopting magnetic drive pump, there is no problem of shaft seal leakage;

- High temperature cooling technology, directly start the compressor to cool down at 300 ℃.

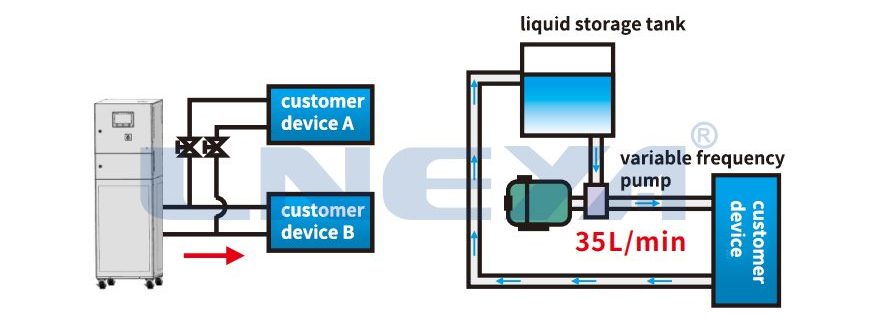

Variable frequency pump can adjust circulating hydraulic pressure and flow

client output signal

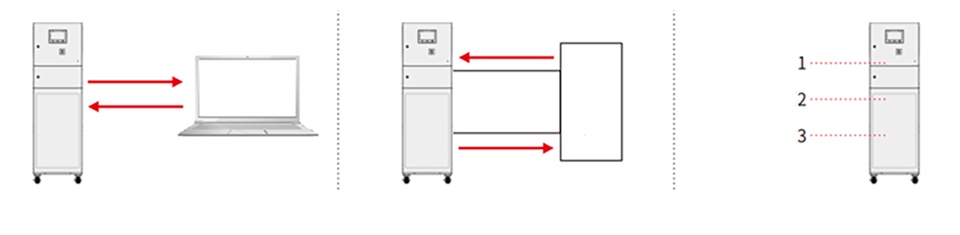

Communication function

APPLICATIONS

Such as chillers that control the processing temperature on the Fab equipments.

Cooling of CMOS/CCD sensors in semiconductor metrology systems.

Recirculating Chiller for semiconductor metering AOI system.

Single channel air-cooled cooler, mainly designed for etching machines. It is used to provide independent temperature control for the chamber side walls.

Used for plasma bevel etch and deposition; Thermal Atomic Layer Etching of Metal Tungsten.

LNEYA provides customized Chiller services

custom chiller sizes

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements. No matter how many tons of chiller you need, we can create the best solution.

custom chiller types

We provide chillers of various refrigeration types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers. Regardless of the type of refrigeration compressor, we can design it according to your requirements.

custom temperature ranges

We can create a custom solution for temperatures from -150℃ to +350℃. Custom temperature ranges for specific industries.

custom chiller voltage

Customize chiller voltage and phase according to your needs. Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

Visit LNEYA factory

Why choose lneya as your temperature control supplier?

Years of experience

Satisfied Customers

m² Production Area

Patented Technologies

contact us

Submit your request to us and we will contact you within 24 hours

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier