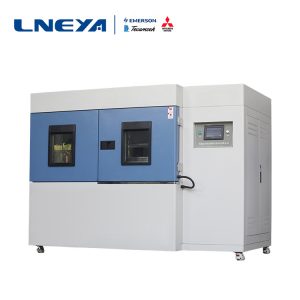

Lneya Semiconductor Refrigeration Heating Circulation Wind System Test Description

There are many test items in the refrigeration and heating circulating air system for semiconductors. So, how much do users know about the out-of-channel testing of the semiconductor refrigeration and heating circulating air system?

The out-of-channel test of the cooling and heating circulating air system for semiconductors refers to the measurement of the frequency bands outside the system frequency. The out-of-channel test is to sample the distortion or interference in the system frequency band, instead of testing the transmission frequency itself. The adjacent channel power ratio (ACPR) test ensures that the transmitter is not interfered by adjacent or spaced channels. ACPR is the ratio of the average power of adjacent channels to the average power of the transmitted channel. Measurements are typically made between channels that are separated by multiple channels (between adjacent channels or spaced channels). When performing ACPR testing, it is important to consider the statistical nature of the transmitted signal, because even for the same transmitter, different signal statistics can result in different ACPR test results. For different standards, the test will usually have different names and definitions.

The cooling signal of the cooling and circulating air system for semiconductors is caused by a combination of different signals in the transmitter. The amplitude of such a signal in the system band must be less than the level specified by the standard to ensure that it has less interference to other communication systems. Harmonics are signal distortions caused by the nonlinearity of the transmitter, and the frequencies of these signals are all integer multiples of the carrier frequency. The test of out-of-channel clutter and harmonics is used to ensure that the interference of this channel to other communication systems is small.

The functions of the receivers for refrigerating and heating circulating air systems for semiconductors are basically the reverse processes of the transmitters, so the test challenges they bring are also very similar. The receiver must successfully capture the RF signal under potentially interfering conditions, so a front-end selection filter must be used to filter out or attenuate signals outside the system band received by the antenna. The low noise amplifier (LNA) amplifies the amplitude of the target signal, but at the same time ensures that the noise amplitude is increased as little as possible. The downconverter converts the RF signal into a lower frequency intermediate frequency signal by mixing with the local oscillator signal. The mixer’s output signal then attenuates the unwanted frequency components produced by the mixer or adjacent channels through the IF filter.

After the relevant test users of the refrigeration and heating circulating air system for semiconductors understand it, they can perform the running test. If there are some problems in operation, it is recommended to contact the semiconductor refrigeration and heating circulating air system manufacturer in time to solve the problem. (This article source network, if there is infringement, please contact delete, thank you.)

Related recommendations

-

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1751The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

View details -

Description of refrigeration principle in semiconductor wafer temperature control

1907In the operation of the semiconductor wafer temperature control refrigeration system, a state transition of a certain working fluid is used, and the necessary heat Q0 is extracted from the heat source of a lower temperature, and the heat Qk is sen...

View details -

The Introductions of the Ultra Low Temperature Recirculating Chillers

1629The performances of ultra low temperature recirculating chillers are different because of their different compressors. Compared with piston compressor, the structure of screw-type compressor tends to be more precise, so when users need to select u...

View details -

Cooling and heating thermostat for running electronic component testing

1680If enterprises want the cooling and heating thermostats for electronic component testing to operate for a long time without any faults, they need to achieve the following points to maintain stable equipment performance. 1. Suitable working enviro...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier