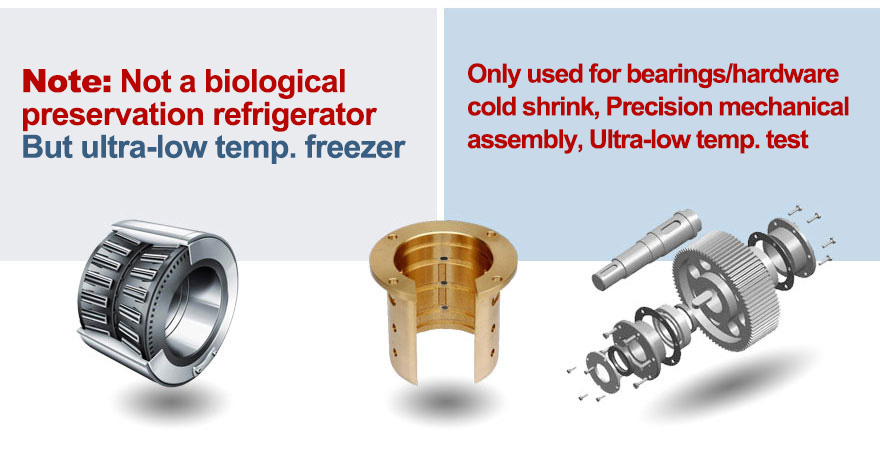

Mechanical cold assembly equipment is dedicated to cold processing assembly of metal parts

Mechanical cold assembly equipment is a method of processing workpieces at temperatures below -130℃. Cryogenic treatment can significantly improve the toughness of the workpiece without reducing the strength and hardness of the workpiece.

Mechanical cold assembly equipment is suitable for containing parts (such as planet carrier, torsion arm, etc.). If the parts cannot be heated or heating parts will cause parts accuracy, material organization changes, and affect their mechanical properties, the contained parts (such as pins and elastic support shafts) can Assembly of frozen interference fittings. The equipment for cold assembly of crankshaft machinery is suitable for all kinds of hot work molds, cold work molds assembly, gears and shafts assembly of various gearboxes, gearboxes, elaborate mechanical parts assembly, various motor stators, rotor assembly, automobile parts Engine parts.

When the hole piece is large or irregular in shape, and the pressed parts are small, cold fitting can be used when it is difficult to implement the method of heating the hole piece. The specific method is to cool the contained part at a low temperature to reduce its size, and then install it into the part with holes.

Mechanical cold assembly equipment can improve the fine structure of the matrix, strengthen the matrix structure, strengthen the dimensional stability, and make the hardness through the cryogenic processing of various tools, cutting tools, molds, drills, secret mechanical parts, nozzles, gears, and bearings. , Impact toughness and wear resistance are significantly improved, effectively extending the service life of the workpiece.

Mechanical cold assembly equipment can transform a large amount of residual austenite in the metal into martensite during cryogenic processing, especially supersaturated metastable martensite will reduce supersaturation from -150 ℃ to room temperature. Precipitation of dispersed ultrafine carbides can reduce martensite lattice distortion and reduce microscopic stress, while finely dispersed carbides can hinder the movement of dislocations during plastic deformation of the material, thereby strengthening the matrix structure. At the same time, due to ultrafine carbide particles After precipitation, they are evenly distributed on the martensite matrix, which weakens the grain boundary embrittlement, and the refinement of the matrix structure not only reduces the degree of segregation of impurity elements in the grain boundary, but also exerts the grain boundary strengthening effect, thereby improving the workmanship. The performance of the mold significantly improves the hardness, impact resistance and wear resistance.

Wuxi Guanya LNEYA specializes in the research, development, manufacturing and sales of cryogenic equipment in the field of low temperature, mainly producing mechanical cold assembly equipment and ultra-low temperature freezer.

Related recommendations

-

Instructions to Use Industrial Cryogenic Refrigerator

1168Industrial refrigerators are one of the cold water machines. It is classified according to the cooling mode of the cold water machine itself. It is divided into air cooling type refrigerators and water cooled refrigerators. Structural features: a ...

View details -

The reason why the semiconductor small thermostat is blocked by refrigeration

1184The small semiconductor small-scale thermostat ice jam is mainly caused by the excessive moisture contained in the refrigeration system. With the continuous circulation of the refrigerant, the moisture in the refrigeration system gradually collect...

View details -

Function of Evaporator in Air Cooled Chiller

1031The air-cooled chiller adopts the air cooling mode, which eliminates the essential cooling tower, cooling water pump and pipeline system of the cooling water system, avoids the condenser scaling and water pipe blockage in areas with poor water qua...

View details -

What are the applications of external circulation oil chillers?

1072External circulation oil chillers are mainly used in the industrial field, especially suitable for situations that require cooling oil to maintain normal equipment operation and extend equipment service life. The following are some typical...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier