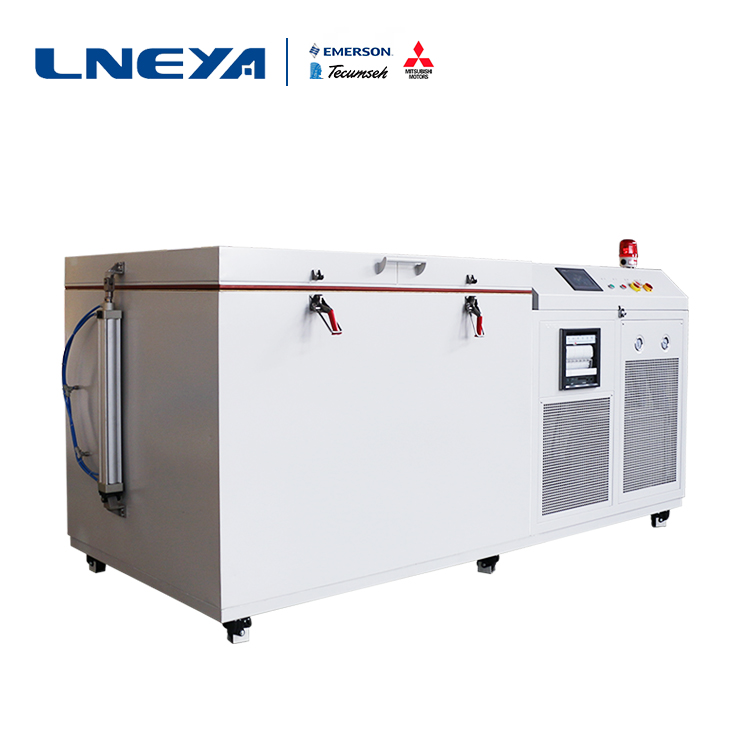

Large industrial refrigerator evaporator operation instructions

In the operation process of Wuxi Guanya LNEYA large industrial refrigerator, due to the large number of parts and complex, we need to understand the operation of the components in large industrial refrigerators. The evaporator is one of the main components, and we need to understand the operation. Better.

The large industrial refrigerator evaporator has good heat transfer effect, compact structure, small volume, convenient installation and wide application, and the structure of the evaporator is the same as that of the horizontal shell-and-tube condenser. The heat transfer coefficient of a tubular evaporator is larger in a liquid than in a gas, and is larger in a flowing state than in a stationary state. In order to control the proper flow rate in the tank, the refrigerant enters from the lower portion of the end cap, flows out from the upper portion, and flows back and forth in the evaporation tube and the end cap to become a multi-program flow. The refrigerant flows outside the tube, and the throttled refrigerant liquid enters from the bottom or side of the evaporator, and the gas after the fins is discharged from the upper portion.

When the shell-and-tube evaporator of a large industrial refrigerator is operated, a certain amount of liquid refrigerant should remain in the casing, and the liquid level is controlled by a float valve. The height of the still water surface should be approximately the diameter of the cylinder. Most of the cooling tubes are immersed in the liquid and exchange heat in a liquid-to-liquid manner.

The materials used in the evaporators in large industrial refrigerators in different industries are different. Typically, the ammonia evaporator is made of 4025 x 2.5-438 x 3 steel tubes and the Freon evaporator is made of copper or brass tubes. In order to improve the heat transfer effect, Freon evaporators mostly use finned tubes. The upper portion of the evaporator barrel is typically filled with fewer rows of cooling tubes or the air pockets are welded to the housing to separate the gas stream before exiting the evaporator. Large evaporators typically produce dedicated separation devices. When the shell and tube evaporator of a large industrial refrigerator is operating, a certain amount of liquid refrigerant should remain in the housing.

Different large industrial refrigerator manufacturers may choose different models when configuring the evaporator, so the user needs to know the configuration clearly when selecting.

Related recommendations

-

The role of temperature control system TCU in chemical and pharmaceutical reactor

1994The temperature control of the reaction kettle in drug research and development and chemical experiments, as well as the temperature control in small-scale experimental production and industrial production processes, require highly dynamic tempera...

View details -

How to maintain stable performance of biopharmaceutical laboratory oil cooler?

13611. A suitable working environment to prevent various failures of the oil cooler in the biopharmaceutical laboratory needs to provide a better operating environment for the equipment. Keep the environment clean and tidy, reduce the impact of vario...

View details -

Advantages of LNEYA heat transfer oil heater

1483The heat transfer oil electric heater is a new type of thermal energy conversion device that uses electricity as the energy source and heat transfer oil as the heat transfer medium. It can provide circulating heat transfer oil of circulating pump ...

View details -

Operating Principle of LNEYA Industrial Air Cooled Chillers

2046Industrial Air Cooled Chillers is a heatexchanger which USES air to cool the hot fluid. The hot fluid in the tube isheated through the exchange of heat between the tube wall, the fin and theoutside air, which is usually supplied by the ventilat...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier