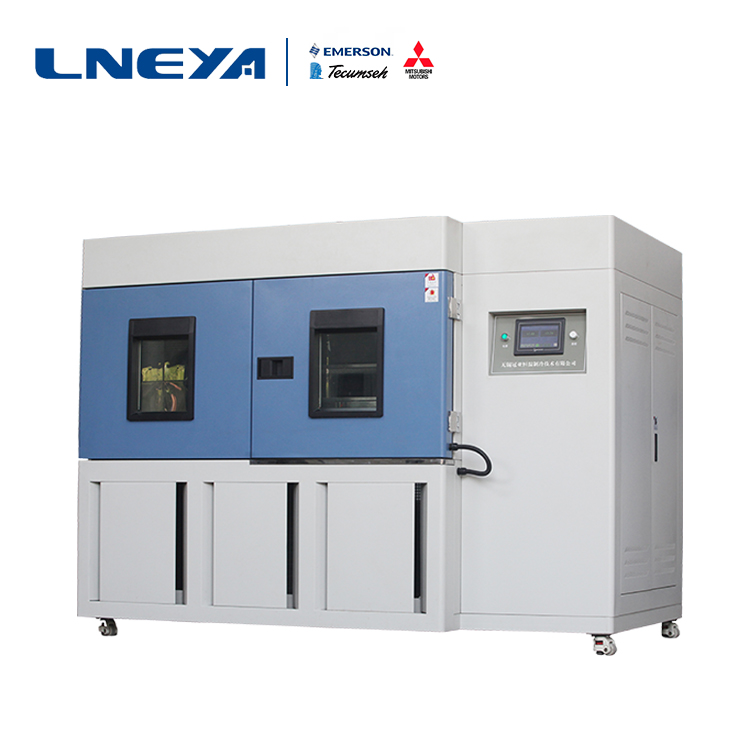

Small high and low temperature impact test chamber volume selection instructions

When the test product (components, components, components or complete machine) is placed in a small high and low temperature impact test chamber for testing, in order to ensure that the atmosphere around the test product can meet the environmental test conditions specified in the test specification, the small high and low temperature impact test There should be some points of attention between the working size of the box and the outer dimensions of the tested product. The volume of the tested product should not exceed (20~35)% of the effective working space of the test box. It is recommended to use no more than 10% for products that generate heat during the test. The ratio of the windward cross-sectional area of the test product to the total area of the test chamber on the section is not more than (35 to 50)%. The distance of the outer surface of the test product from the wall of the test chamber is at least 100 to 150 mm.

After the test piece is placed in the box, the smooth passage is occupied, and the narrowing of the passage will result in an increase in the flow rate of the air flow. Accelerate the heat exchange between the gas stream and the test piece. This is inconsistent with the reproduction of environmental conditions, because in the relevant standards, the temperature flow around the test specimens in the test chamber should not exceed 1.7 m/s, so as to prevent the test specimens and the surrounding atmosphere from being produced. Heat transfer. If the volume of the test piece or the wind-breaking area is increased without restriction in the test, the airflow speed will increase beyond the wind speed specified in the test standard during the actual test, and the validity of the test results will be suspected.

The accuracy index of the environmental parameters in the working chamber of the small high and low temperature impact test chamber is the result of the test under no-load condition. Once the test piece is placed, the uniformity of the environmental parameters in the working chamber of the test box will be affected. The greater the space occupied, the more serious this effect will be.

According to the principle of heat conduction, the temperature of the gas flow near the tank wall is usually 2 to 3 °C from the center temperature of the flow field, and may reach 5 °C at the upper and lower limits of the high and low temperature. The temperature of the tank wall is different from the temperature of the flow field near the tank wall by 2~3 °C (depending on the structure and material of the tank wall). The greater the difference between the test temperature and the external atmospheric environment, the greater the above temperature difference, therefore, the distance from the tank wall The space within the distance (100 to 150 mm) is an unusable space.

The volume selection instructions above the small high and low temperature impact test chamber do not know that you understand it. I believe that users can better select the equipment after reading these.

Related recommendations

-

Why do special gases used in semiconductor manufacturing processes require chillers?

1340When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons: 3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition...

View details -

Why is the mode of cooling water circulator mainly water circulation?

1370Cooling water circulator is a way to use water for cooling. With the increase in ambient temperature, many companies have also found that the use of circulating water is increasing. The supplement of circulating water is aimed at the water cooling...

View details -

Precautions for installation of special chiller for new energy testing

1514The installation of the special chiller for new energy testing is an important link before operation. The quality of the installation is directly related to the operation and operation status of the special chiller for new energy testing. So, what...

View details -

Closed circulation cooling system debugging attention note

1587Closed circulation cooling system needs to pay attention to some common problems during commissioning. Do a good job in debugging work. LNEYA manufacturers remind users that only when they are ready to work can they be better debugged. The prepara...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier