High and low temperature device related instrument maintenance instructions

The liquid medium should be added before the high and low temperature circulation device is used. The liquid medium generally uses more than 95% alcohol, and the liquid medium cannot be lower than the working plate 20mm. The high and low temperature circulation pump should be placed in a dry and ventilated place with a distance of 400 mm from the obstacle on the back and sides. The working power supply of the high and low temperature circulating device should be determined according to the model of the machine (technical parameter column). The power of the power supply should be greater than or equal to the total power of the instrument. The power supply must have a good “grounding” device (Note: low temperature coolant circulating pump 380v voltage There is a grounding lead on the screw on the lower left side of the instrument). After the high and low temperature circulation device is used, all the switches must be turned off before the power plug can be unplugged. The high and low temperature device manufacturers use the suction ball and the skin tube to suck the liquid.

If the high and low temperature circulation device is operated below 0 °C, the door should be avoided as much as possible. Because when the temperature is low, if the door is opened, the internal evaporator and other parts will be sealed, especially the lower the temperature, the more serious the situation is. If you must open it, you should try to shorten the opening time. When the low temperature operation is completed, it is necessary to set the temperature condition at 60 ° C for drying for about half an hour, so as not to affect the measurement time or icing phenomenon of the next working condition. The high and low temperature circulation device radiator (condenser) should be regularly maintained and kept clean. After the low-temperature operation of the high-low temperature cycle device, if there is no work at the sixth point above, it is also necessary to set the normal temperature condition so that the temperature inside the box is normal temperature when the machine is stopped, so as not to affect the icing phenomenon caused by the low temperature inside the box. And the fogging of the window glass.

The use of high and low temperature circulation devices requires frequent maintenance, and proper maintenance can prolong the service life of the high and low temperature circulation devices and stabilize the operation.

Related recommendations

-

Process description of LNEYA screw chiller

1517LNEYA screw chiller is suitable for all kinds of chemical, pharmaceutical, mechanical and other fields of production process cold source, can provide -25 ° C ~ 30 ° C chilled water, can be used as ice cold storage, low temperature air supply and o...

View details -

Step-by-step test box brand advantage description

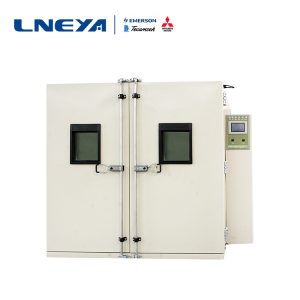

1764The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

View details -

Why is the mode of cooling water circulator mainly water circulation?

1370Cooling water circulator is a way to use water for cooling. With the increase in ambient temperature, many companies have also found that the use of circulating water is increasing. The supplement of circulating water is aimed at the water cooling...

View details -

Reactor Thermal Control Unit and Solutions for Chemicals

2121Temperature control is a process in which the temperature of a substance or a change in temperature is measured or otherwise detected, and the transfer of thermal energy into or out of the space or substance is adjusted to achieve the desired temp...

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier