The Inevitable Development Of New Energy Vehicle Battery Test Cooling Device

New energy vehicle battery test cooling device

The energy crisis and environmental pollution have spawned the development of new energy vehicles. The key to the technology of new energy vehicles is the performance of power batteries. There are many types of power batteries, such as lead-acid batteries, nickel-cadmium batteries, nickel-metal hydride batteries, and lithium-ion batteries. Zinc air battery, fuel battery, etc., power battery pack is an important part of electric vehicles, directly affecting the electric vehicle’s starting, acceleration, mileage and other performance.

Therefore, the testing of the power battery pack by the new energy vehicle battery test cooling device is an important part of the development of the electric vehicle. The battery management system is closely integrated with the battery to detect the voltage, current and temperature of the battery at the same time, and also conduct leakage. Detection, thermal management, battery balance management, alarm reminder, calculate remaining capacity, discharge power, and control the output power according to the voltage, current and temperature of the battery to obtain the maximum mileage, and use the algorithm to control the charging of the charger. The bus interface communicates with the vehicle master controller, motor controller, energy control system, and vehicle display system in real time.

The new energy vehicle battery test cooling device is a check on the new energy battery. It also needs to manage the battery system, monitor the battery status in real time, and use the appropriate algorithm by detecting the external characteristic parameters of the battery (such as voltage, current, temperature, etc.). To realize the estimation and monitoring of the internal state of the battery (such as capacity and SOC), which is the basis and key for the effective operation of the battery management system. After correct acquisition of the state of the battery, thermal management, battery balance management, charge and discharge management, and fault alarm are performed. Etc; establish a communication bus to implement data exchange to display systems, vehicle controllers, and chargers.

The development of new energy vehicle battery test cooling device equipment is also quite competitive in the current new energy market. Therefore, only on the basis of its original, it is necessary to strengthen the performance of new energy vehicle battery test cooling device equipment, occupying The favorable position of the market.

Related recommendations

-

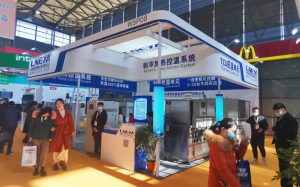

Exhibition Preview | 2019 China International Automotive Testing Quality Monitoring Expo

1779Autumn is cool, the exhibition season is here again!For you to present Wuxi Guanya LNEYA exhibition information: We invite you to attend:2019 China International Automotive Testing and Quality Control ExpoExhibition time: September 24-26Exhibi...

View details -

-

How to replace the four-way valve of the chilled water machine?

1671The four-way valve of the chilled water machine needs to be replaced in time after a long period of use, so how to replace it? You can look at the suggestions. When replacing the chilled water machine, you need to remove the connecting pipe conne...

View details -

New energy vehicle battery motor test motor oil chiller and liquid chiller

1703New energy vehicle battery testing chiller

View details

LNEYA Industrial Chillers Manufacturer Supplier

LNEYA Industrial Chillers Manufacturer Supplier